ZCL

Spur Gears

Description

Material

Glass-fibre reinforced polyamide-based (PA) technopolymer, grey colour.

Standard executions

- ZCL-0.5: module 0.5 solid hub (number of teeth Z ≤ 50) or pre-drilled pass-through hole (number of teeth Z ≥ 55).

- ZCL-1.0: module 1.0 solid hub (number of teeth Z = 10) or pre-drilled pass-through hole.

- ZCL-1.5: module 1.5, pre-drilled pass-through hole

- ZCL-2.0: module 2.0, pre-drilled pass-through hole

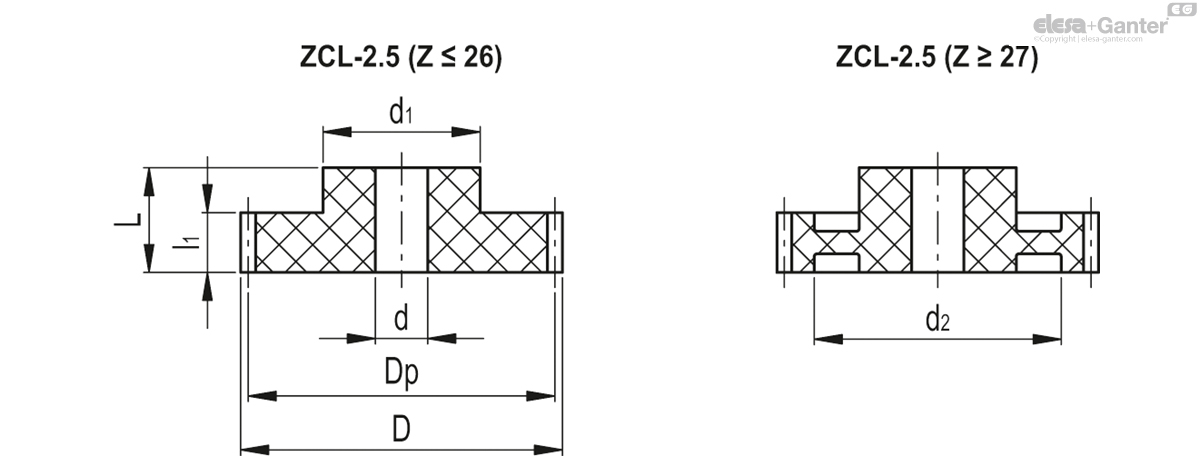

- ZCL-2.5: module 2.5, pre-drilled pass-through hole

- ZCL-3.0: module 3.0, pre-drilled pass-through hole

- ZCL-1.0-K: module 1.0, drilled hub with keyway UNI 6604, D10 tolerance.

- ZCL-1.5-K: module 1.5, drilled hub with keyway UNI 6604, D10 tolerance.

- ZCL-2.0-K: module 2.0, drilled hub with keyway UNI 6604, D10 tolerance.

- ZCL-2.5-K: module 2.5, drilled hub with keyway UNI 6604, D10 tolerance.

- ZCL-3.0-K: module 3.0, drilled hub with keyway UNI 6604, D10 tolerance.

For the executions with the pre-drilled pass-through hole, in the tables the size “d” of the hole represents the minimum diameter of the hole that can be obtained through machining.

For the -K versions, the keyway machining does not necessarily result in phasing with the gearing.

Features

The torques indicated in the tables are granted with rpm included between 0 and 150. Torque values can vary depending on lubrication, temperature, pairing with different materials and continuous operating hours.

Maximum tolerance on plain pass-through hole: IT 9.

Technical data

See: Transmission elements.

Special executions on request

- Assembly by means of a transversal grub screw.

- Various non-standard gears with hub with keyway according to UNI 6604 tolerance D10.

Mounting

To pair two spur gears, a positive backlash must be considered. For modules 0.5 - 1.0 - 1.5 is recommended the tolerance (+0.03 +0.1). For modules 2.0 - 2.5 - 3.0 is recommended the tolerance (+0.08 +0.3).

ZCL-2.5

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.