ZCP

Spur Gears

Description

Material

Acetal resin based (POM-C) technopolymer, white colour.

Standard executions

- H10 reamed pass-through hole.

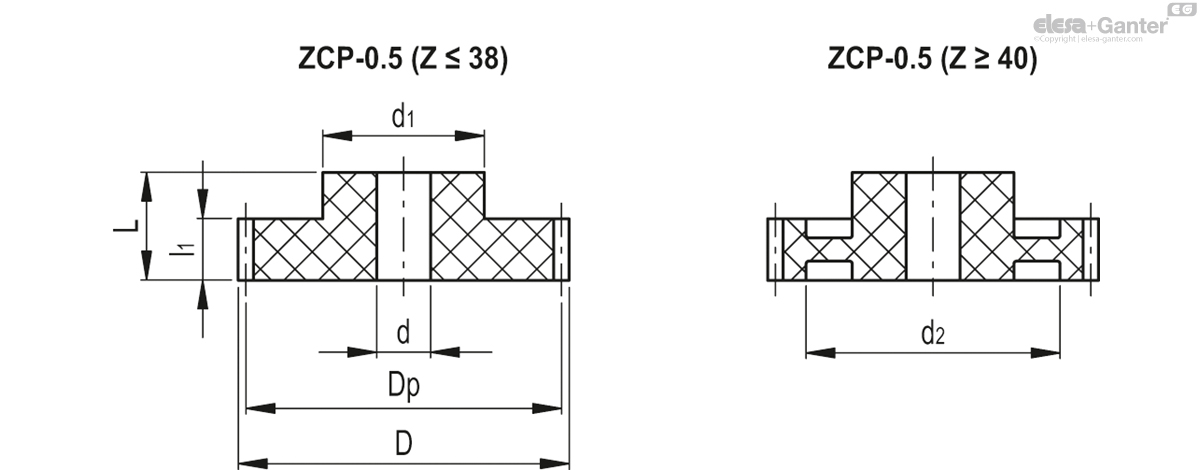

- ZCP-0.5: module 0.5.

- ZCP-0.7: module 0.7.

- ZCP-1.0: module 1.0.

- ZCP-1.25: module 1.25.

- ZCP-1.5: module 1.5.

- ZCP-2.0: module 2.0.

- ZCP-3.0: module 3.0.

Features

The torques indicated in the tables are granted with rpm included between 0 and 150. Torque values can vary depending on lubrication, temperature, pairing with different materials and continuous operating hours.

Excellent sliding properties, reduced coefficient of friction, and high resistance to wear and tear make this product suitable for high rotation speeds (above 1,000rpm) even in the absence of lubrication.

The acetal resin based technopolymer makes the product suitable for use in food sectors, in humid environments, and guarantees high resistance to chemical agents, including many solvents.

Technical data

See: Transmission elements.

Special executions on request

- Hub with threaded grub screw

- Hub with hole and keyway in compliance with UNI 6604

Mounting

To pair two spur gears, a positive backlash must be considered.

For modules 0.5 – 0.7 – 1.0 – 1.25 – 1.5 is recommended the tolerance (+0.03 +0.1). For modules 2.0 - 3.0 is recommended the tolerance (+0.08 +0.3).

The H10 reamed hole allows the gear to be mounted on the shaft. In the case of application with low torques, a hole and keyway for coupling is not necessary as a threaded screw is sufficient. It is not recommended to enlarge the hole by more than 2mm with respect to the diameter shown in the tables, to avoid the occurrence of cracks in the material.

ZCP-0.5

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.