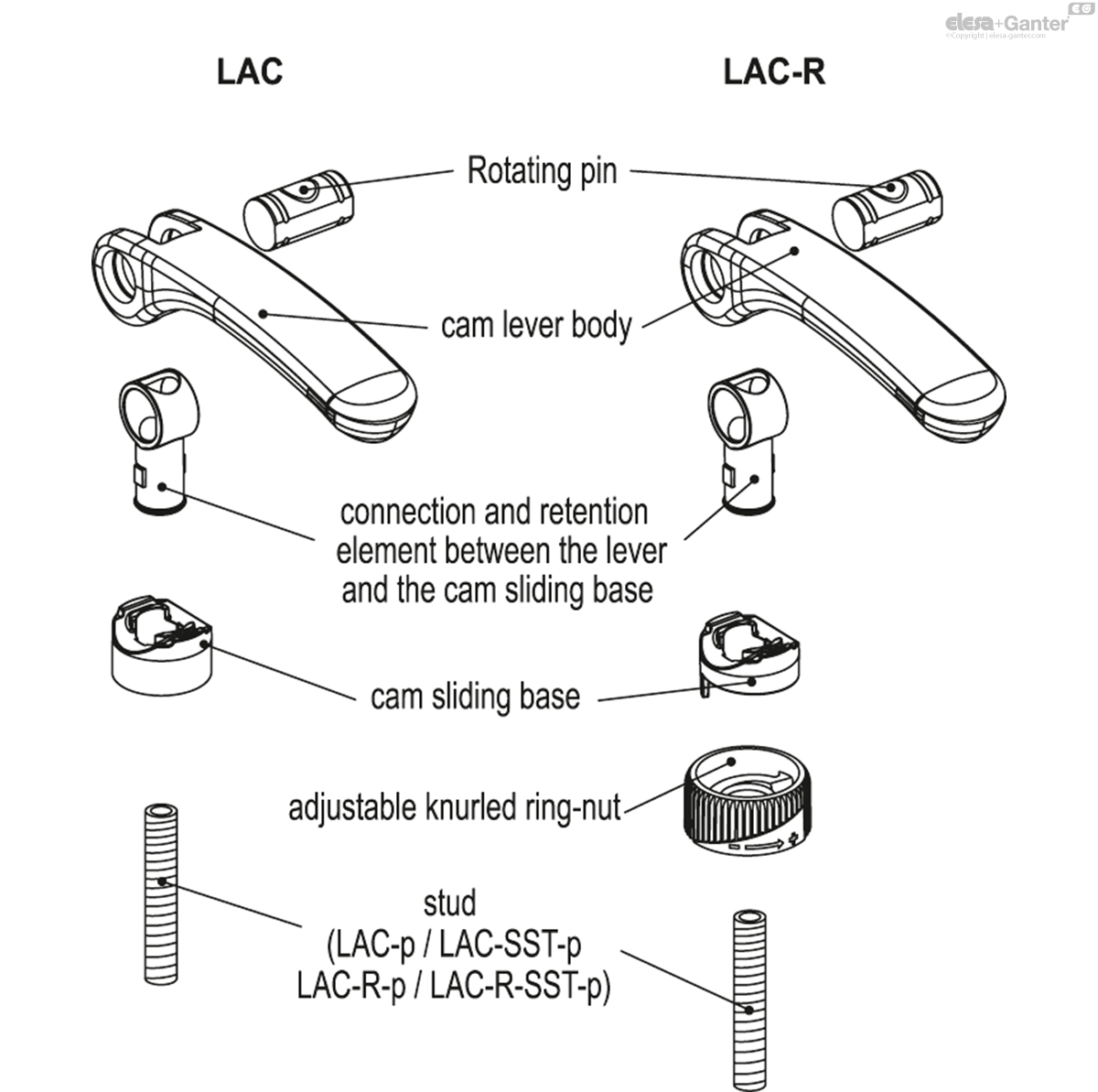

LAC.

Cam clamping levers

Description

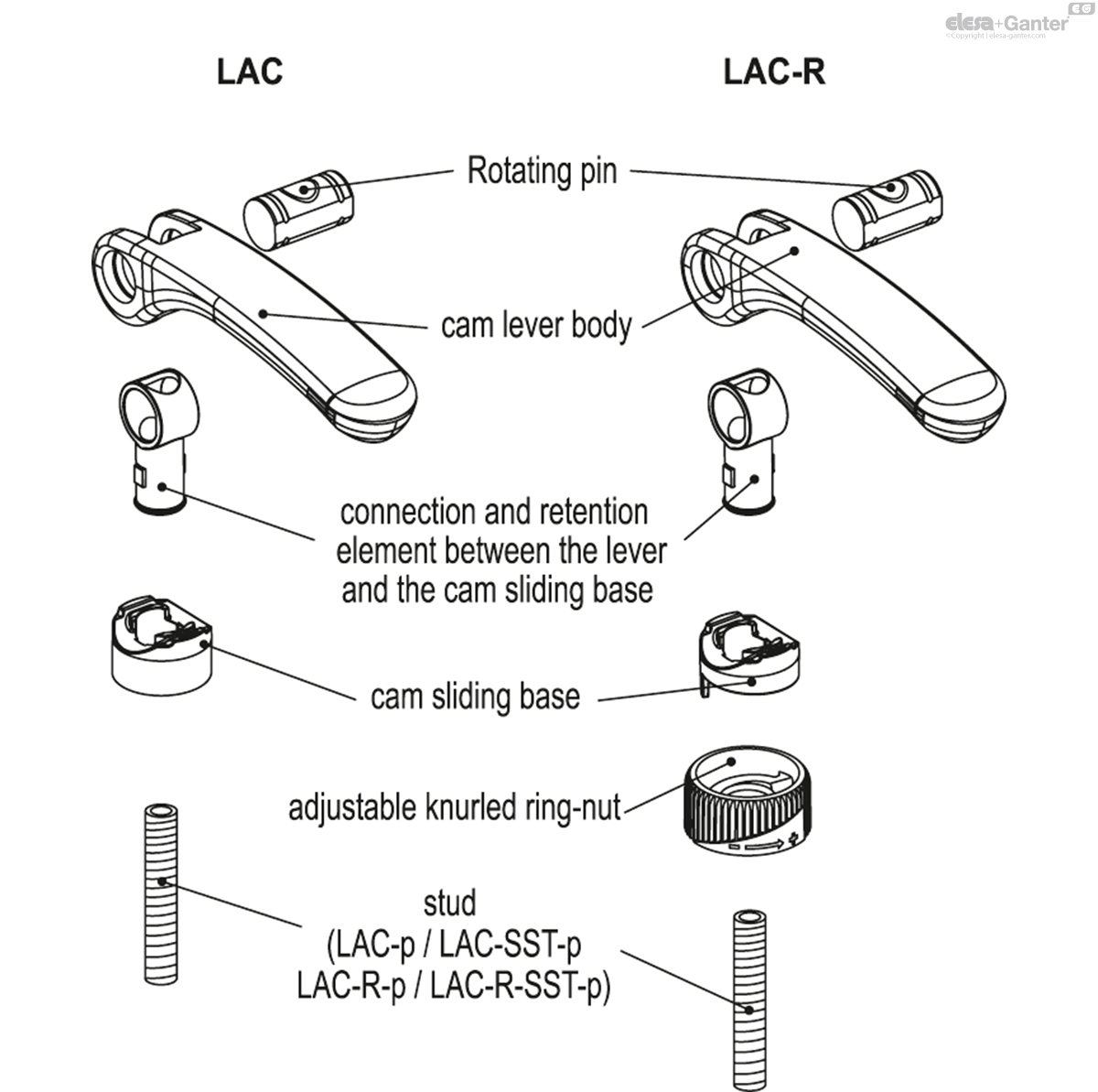

Cam lever body

Glass-fibre reinforced polyamide based (PA) technopolymer, black colour, matte finish.

Rotating pin

Glossy zinc-plated steel or AISI 303 stainless steel, with threaded hole or threaded stud.

Connection and retention element between the lever and the cam sliding base

Polyamide based (PA) technopolymer, black colour.

Cam sliding base

Polyamide-based SUPER-technopolymer (PA), black colour.

Adjustable knurled ring-nut

Polyamide-based SUPER-technopolymer (PA), black colour.

Standard executions

- LAC-B: positioning without adjustable ring-nut, rotating pin with zinc-plated steel threaded hole.

- LAC-SST: positioning without adjustable ring-nut, rotating pin with AISI 303 stainless steel threaded hole.

- LAC-p: positioning without adjustable ring-nut, rotating pin with zinc-plated steel threaded stud, chamfered flat end UNI 947: ISO 4753 Technical data).

- LAC-SST-p: positioning without adjustable ring-nut, rotating pin with AISI 303 stainless steel threaded stud, chamfered flat end UNI 947: ISO 4753 Technical data).

- LAC-B-R: positioning with adjustable ring-nut, rotating pin with zinc-plated steel threaded hole.

- LAC-SST-R: positioning with adjustable ring-nut, rotating pin with AISI 303 stainless steel threaded hole.

- LAC-p-R: positioning with adjustable ring-nut, rotating pin with threaded stud in zinc-plated steel, chamfered flat end UNI 947: ISO 4753 (see Technical data).

- LAC-SST-p-R: positioning with adjustable ring-nut, rotating pin with threaded stud in AISI 303 stainless steel, chamfered flat end UNI 947: ISO 4753Technical data).

Features and applications

Cam lever is a device which allows a quick and secure clamping.

The LAC-R model with adjustable ring-nut (ELESA patent) offers quick and secure clamping. The knurled ring-nut on the base allows to adjust the clamping force applied while locking the lever in the desired position.

Special executions on request

Cam clamps with connection element, not drilled for a better cleaning (for sufficient quantities).

Recommendations for assembly

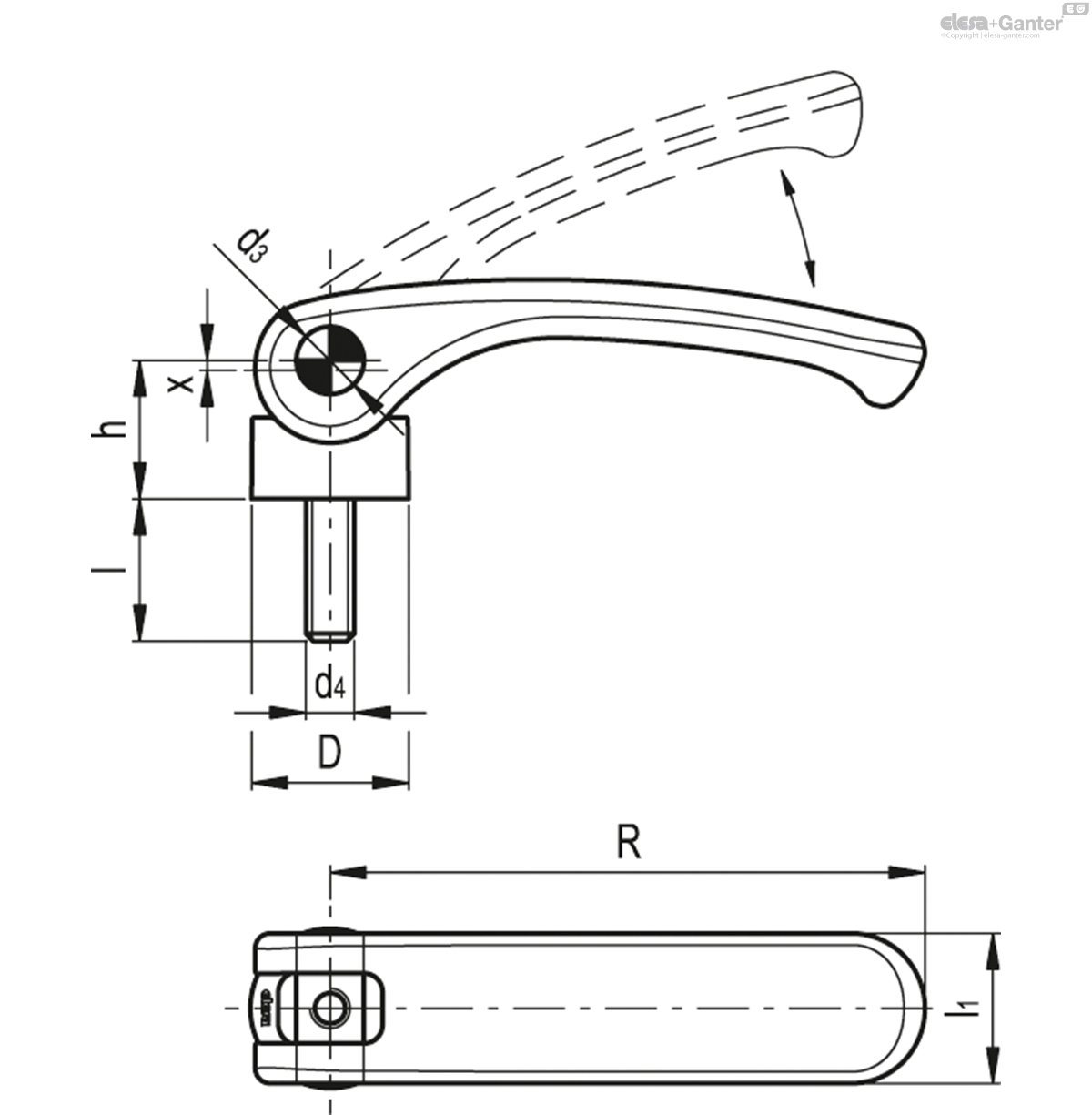

LAC-B, LAC-SST, LAC-B-R and LAC-SST-R with threaded hole. The screw where the cam lever is mounted must protrude from the assembly surface by a maximum length of h1 max from the end-stop as shown in table and Fig.1. The user will notice the h1 max value is reached as the screw rests on the end-stop in the connecting element.

Instructions for clamping and adjustment

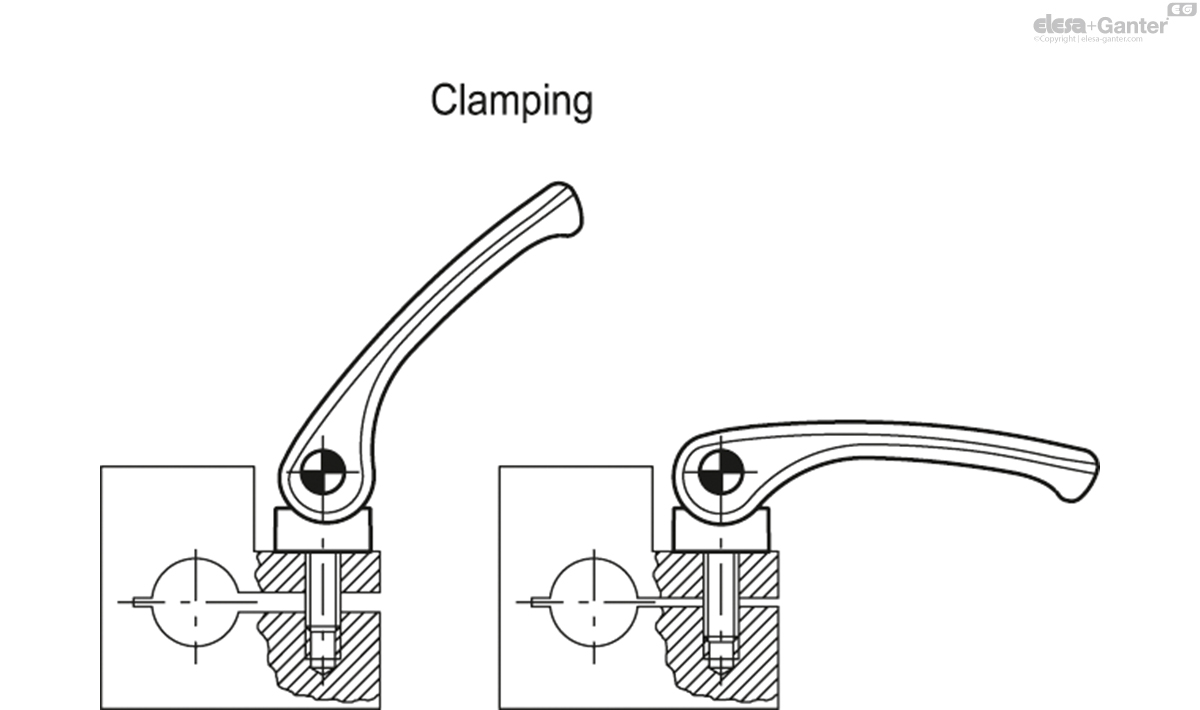

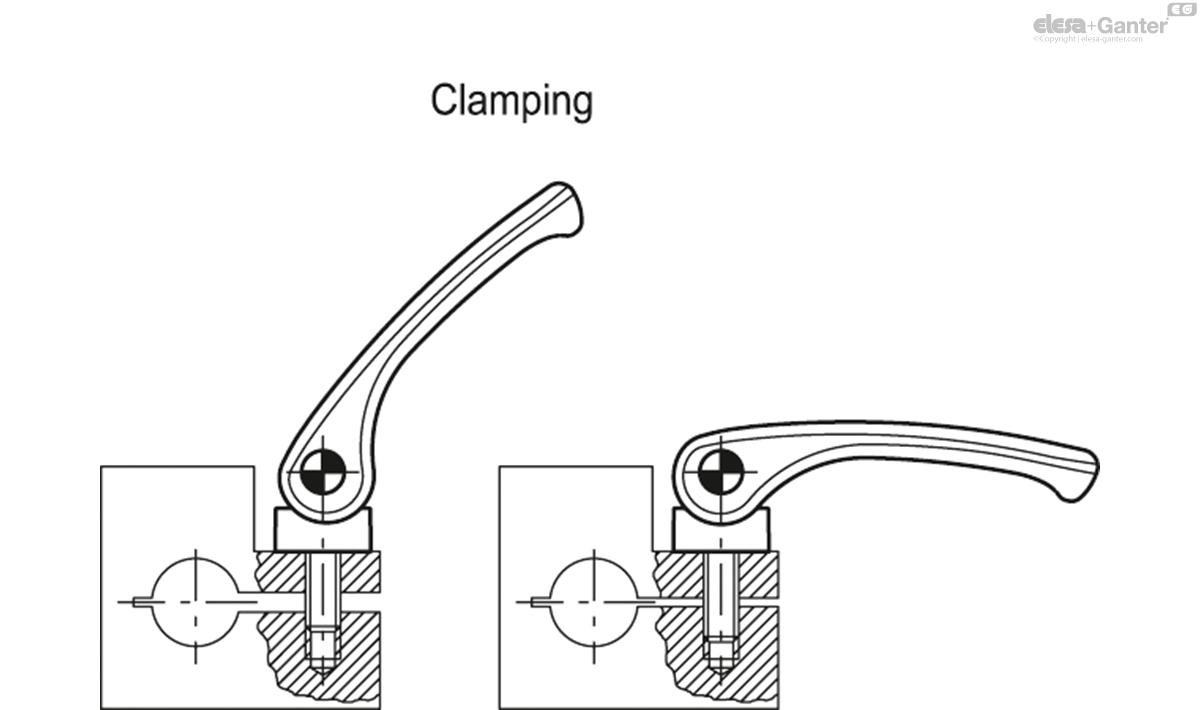

- LAC: lift and rotate the lever clockwise until it stops, then, to complete clamping, lower the lever whose fulcrum is an eccentric cam which controls the base by rotating.

- LAC-R: rotate the lever clockwise until it stops.

Fine adjustment: rotate clockwise or anti-clockwise the knurled adjustable ring-nut to calibrate the clamping force and put the lever in the desired position. The ring-nut is marked with minimum and maximum adjustment values: half a turn is enough for adjustment.

Clamping: lower the lever whose fulcrum is an eccentric cam which controls the adjusting base by rotating.

LAC-SST-p

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.