GN 918.5

Eccentric Cams

Description

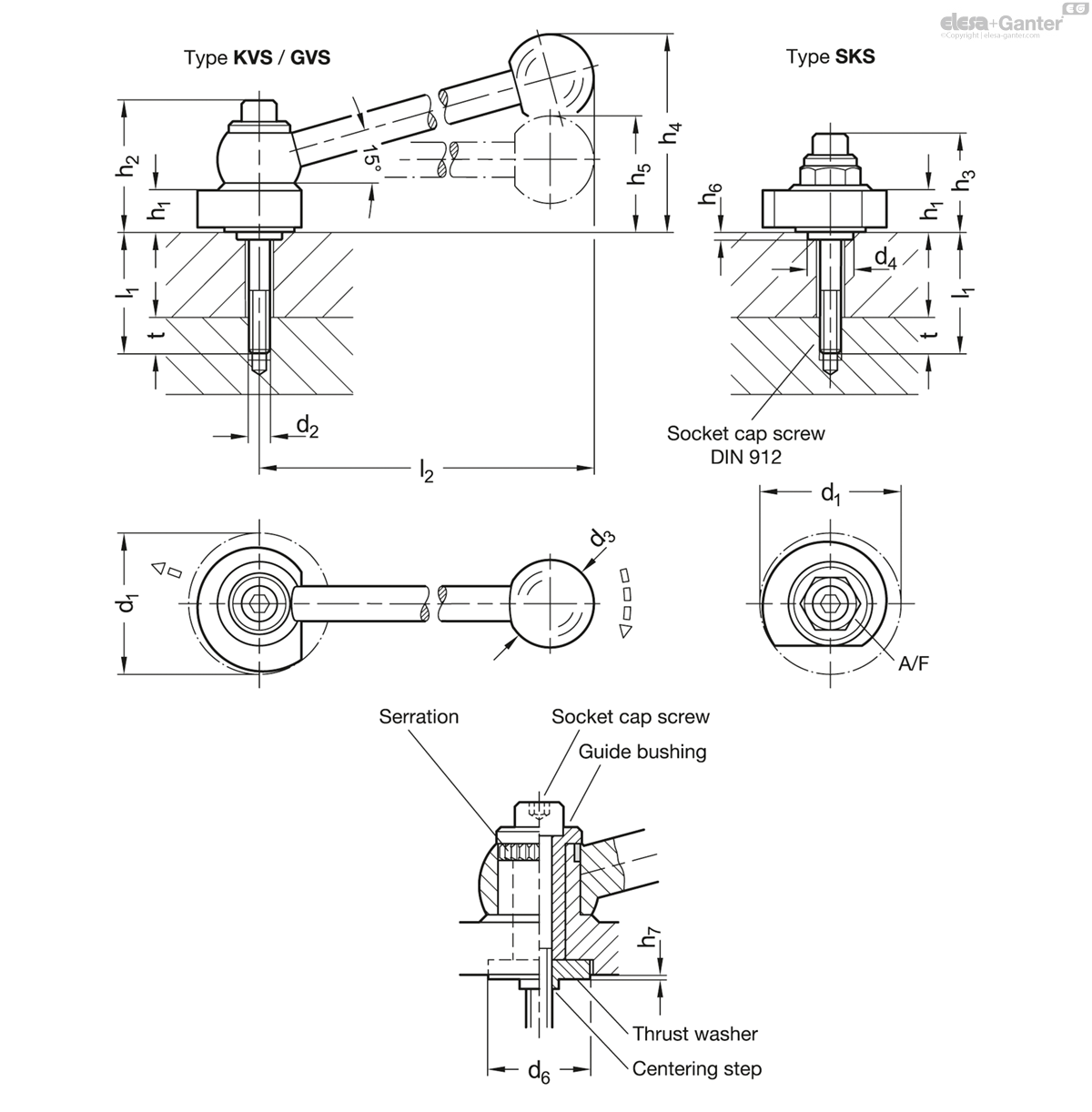

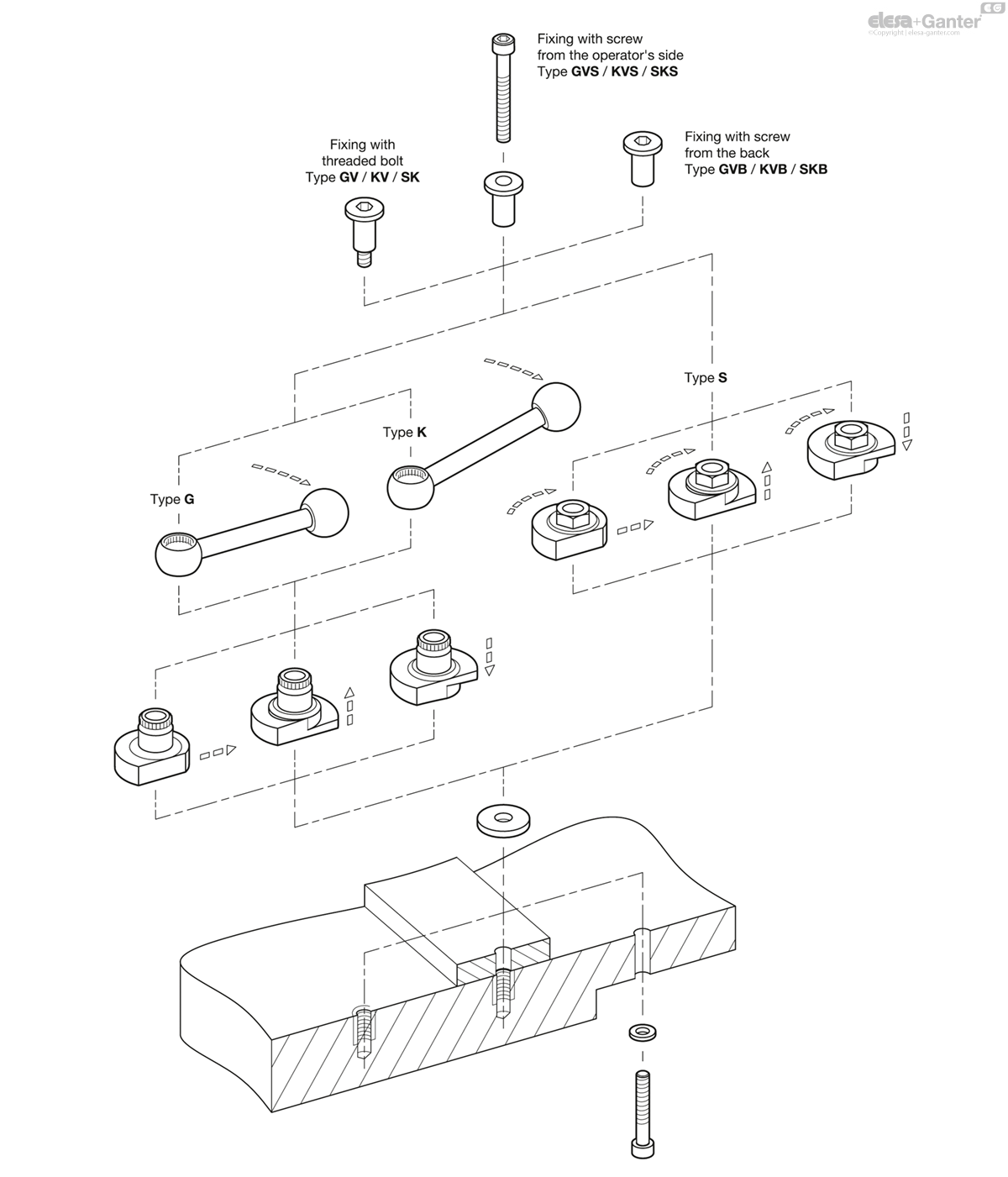

Types

- Type KV / KVS / KVB: With ball lever, angular (serration)

- Type GV / GVS / GVB : With ball lever, straight (serration)

- Type SK / SKS / SKB: With hex

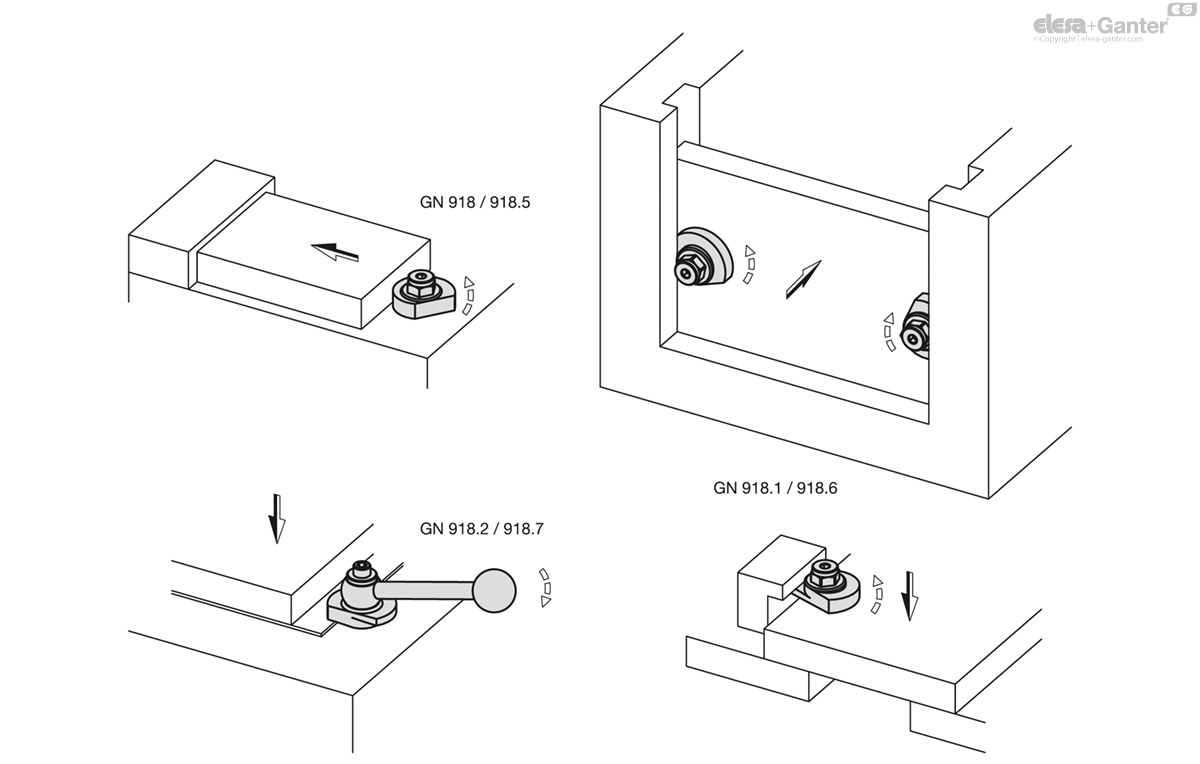

Clamping direction

- Type R: By clockwise rotation (drawn version)

- Type L: By anti-clockwise rotation

Stainless steel

Version with Threaded Bolt

- Eccentric cam

AISI 303, chemically nickel plated

- Threaded bolt and thrust washer

AISI 630, tempered

- Lever

AISI 303, matte shot-blasted

Version with Screw from the Operator‘s Side

- Eccentric cam

AISI 303, chemically nickel plated

- Guide bushing and thrust washer

AISI 630, tempered

- Socket cap screw DIN 912-A2-70

- Lever

AISI 303, matte shot-blasted

Version with Screw from the Back

- Eccentric cam

AISI 303, chemically nickel plated

- Threaded bushing, thrust washer and washer

AISI 630, tempered

- Socket cap screw DIN 912-A2-70

- Lever

AISI 303, matte shot-blasted

Ball knob DIN 319

Plastic, Duroplast

Black, shiny finish

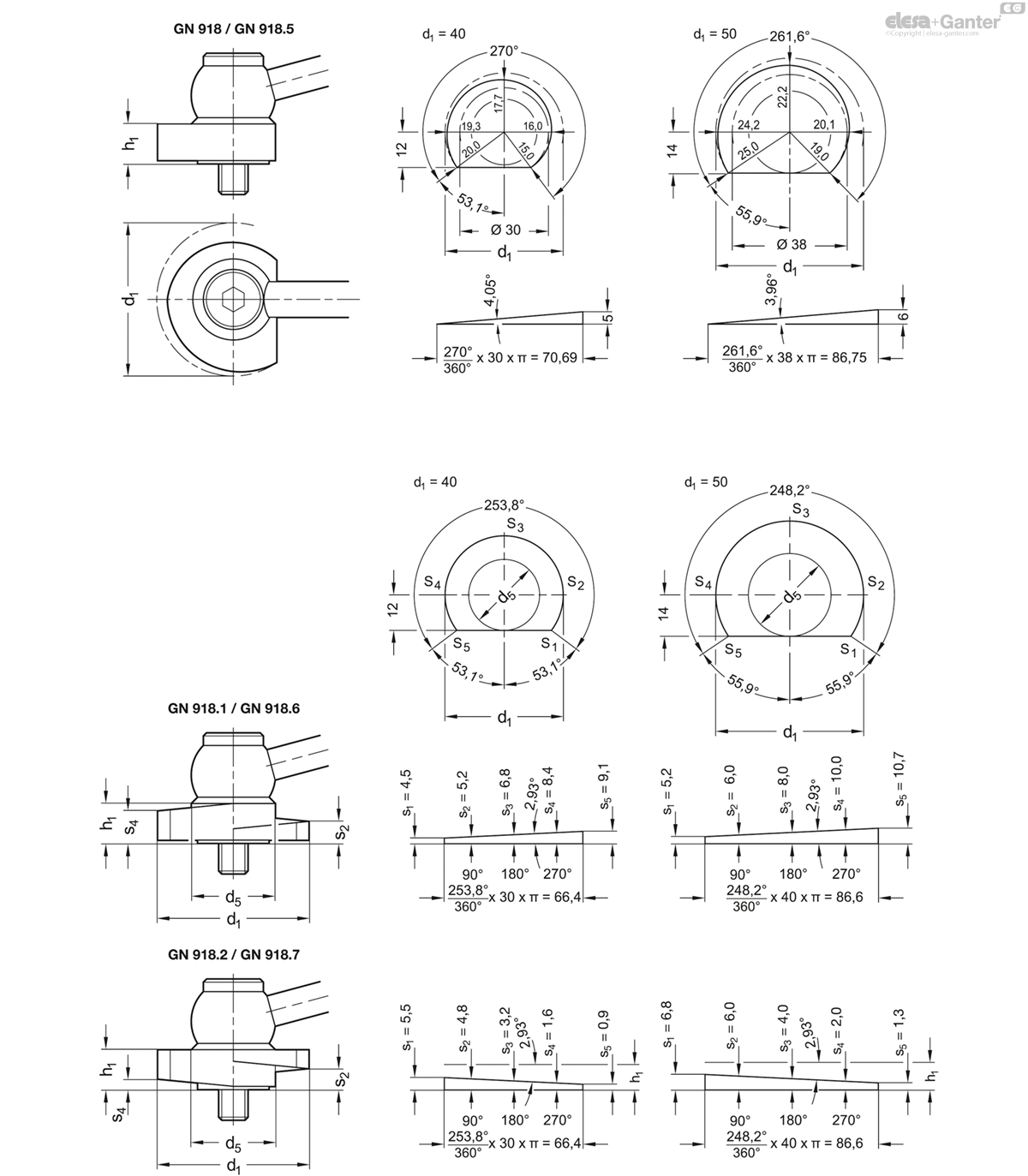

Eccentric cams GN 918.5 allow the rapid and secure clamping and releasing at a relatively large clamping range and with high clamping force. The cam offers the advantage that the clamping force remains constant in every angular and is self-locking at the same time. The ball levers of types KV / KVS / KVB and GV / GVS / GVB feature a positive connection with the eccentric cam by means of a serration. During assembly, the position of the lever can thus be fixed in a position that is favorable for clamping.

Version with Threaded Bolt

The use of the thrust washer eliminates the need for special requirements on the execution of the threaded hole, so that it can also be mounted on tables with T-slots, for example.

Version with Screw from the Operator‘s Side

Fastening via screw from the operator’s side bridges a larger clamping range. A sufficiently large screw-in depth t is necessary to safely absorb the screw forces. The centering step of the thrust washer provides protection from impermissible lateral forces on the socket cap screw.

Version with Screw from the Back

Fastening the screw from the back allows the use, if there is no thread in the surrounding structure. The heavy duty washer absorbs and transfers the resulting screw forces. The centering step of the thrust washer provides protection from impermissible lateral forces on the socket cap screw.

- Technical instructions

- Strength Values of Screws

- Plastic Characteristics

- Stainless Steel Characteristics

GN 918.5-GVS

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.