GN 918.2

Clamping Bolts

Description

Types

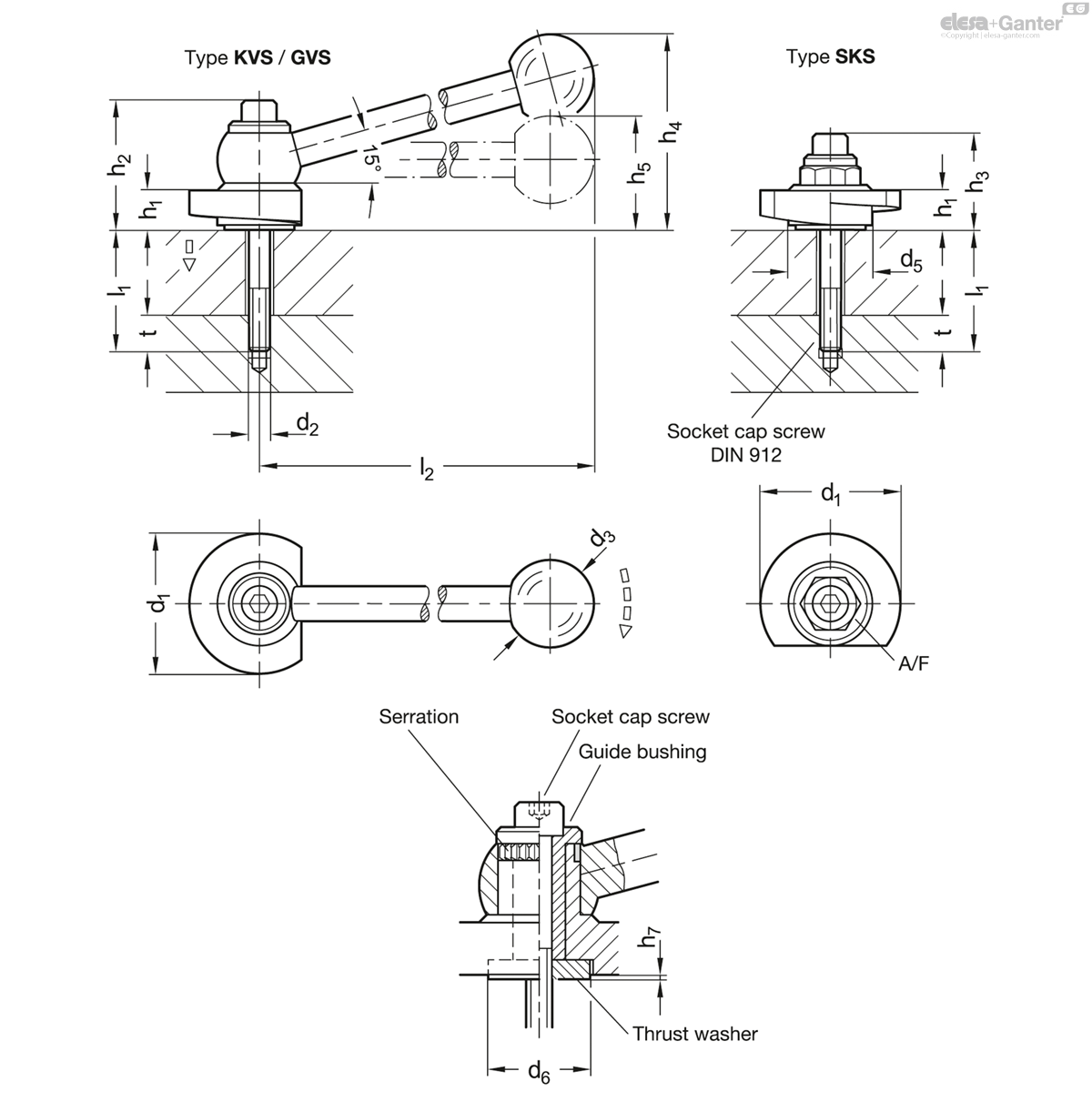

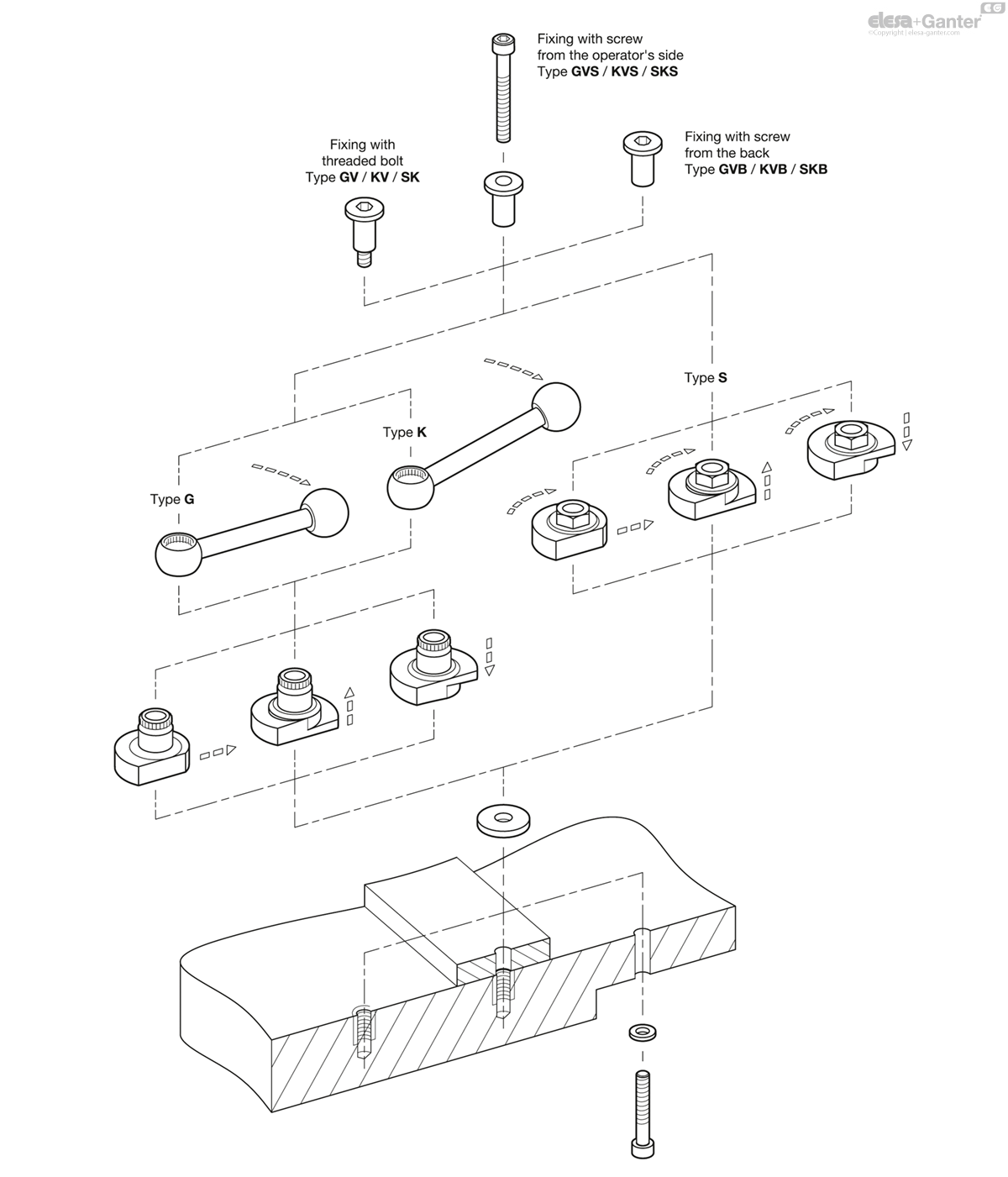

- Type KV / KVS / KVB: With ball lever, angular (serration)

- Type GV / GVS / GVB : With ball lever, straight (serration)

- Type SK / SKS / SKB: With hex

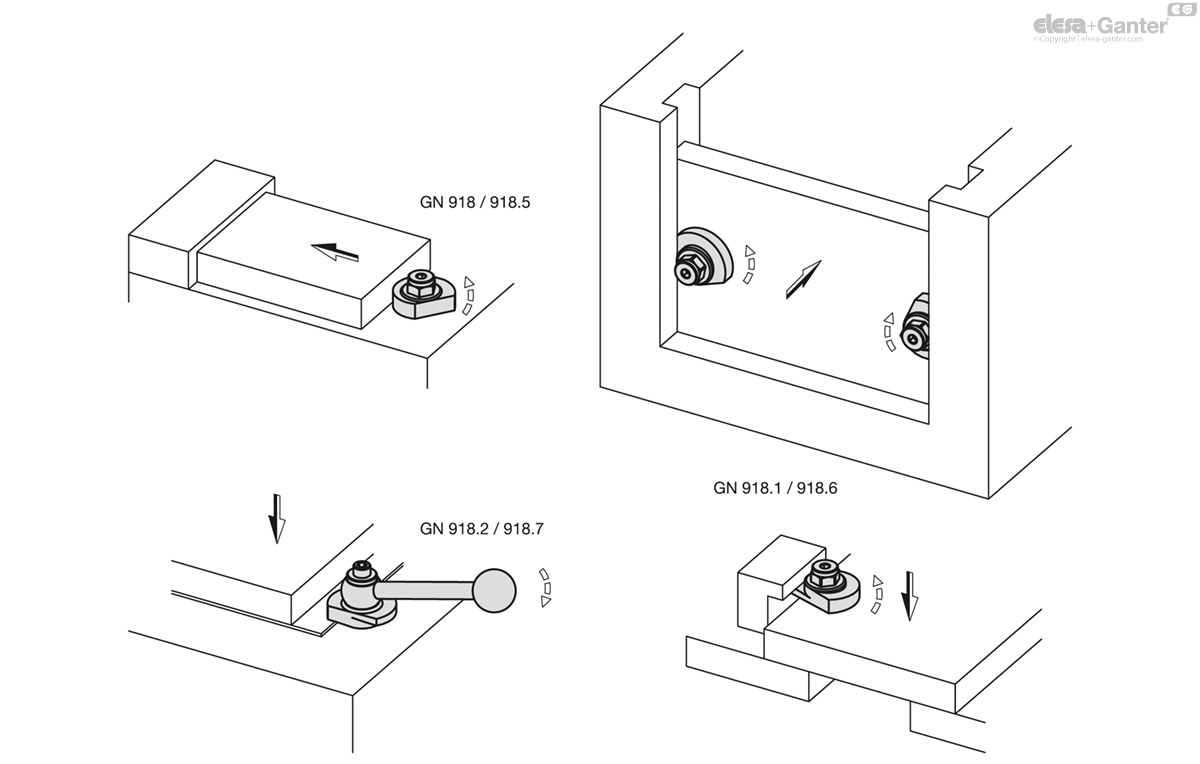

Clamping direction

- Type R: By clockwise rotation (drawn version)

- Type L: By anti-clockwise rotation

Steel

Version with Threaded Bolt

- Clamping bolt and thrust washer

Case-hardened

- Threaded bolt nitrided

Property class 8.8

- Lever blackened

Version with Screw from the Operator‘s Side

- Clamping bolt, guide bushing and thrust washer

Case-hardened

- Socket cap screw DIN 912-12.9

- Lever blackened

Version with Screw from the Back

- Clamping bolt, threaded bushing and thrust washer

Case-hardened

- Socket cap screw DIN 912-12.9

- Washer tempered

- Lever blackened

Ball knob DIN 319

Plastic, Duroplast

Black, shiny finish

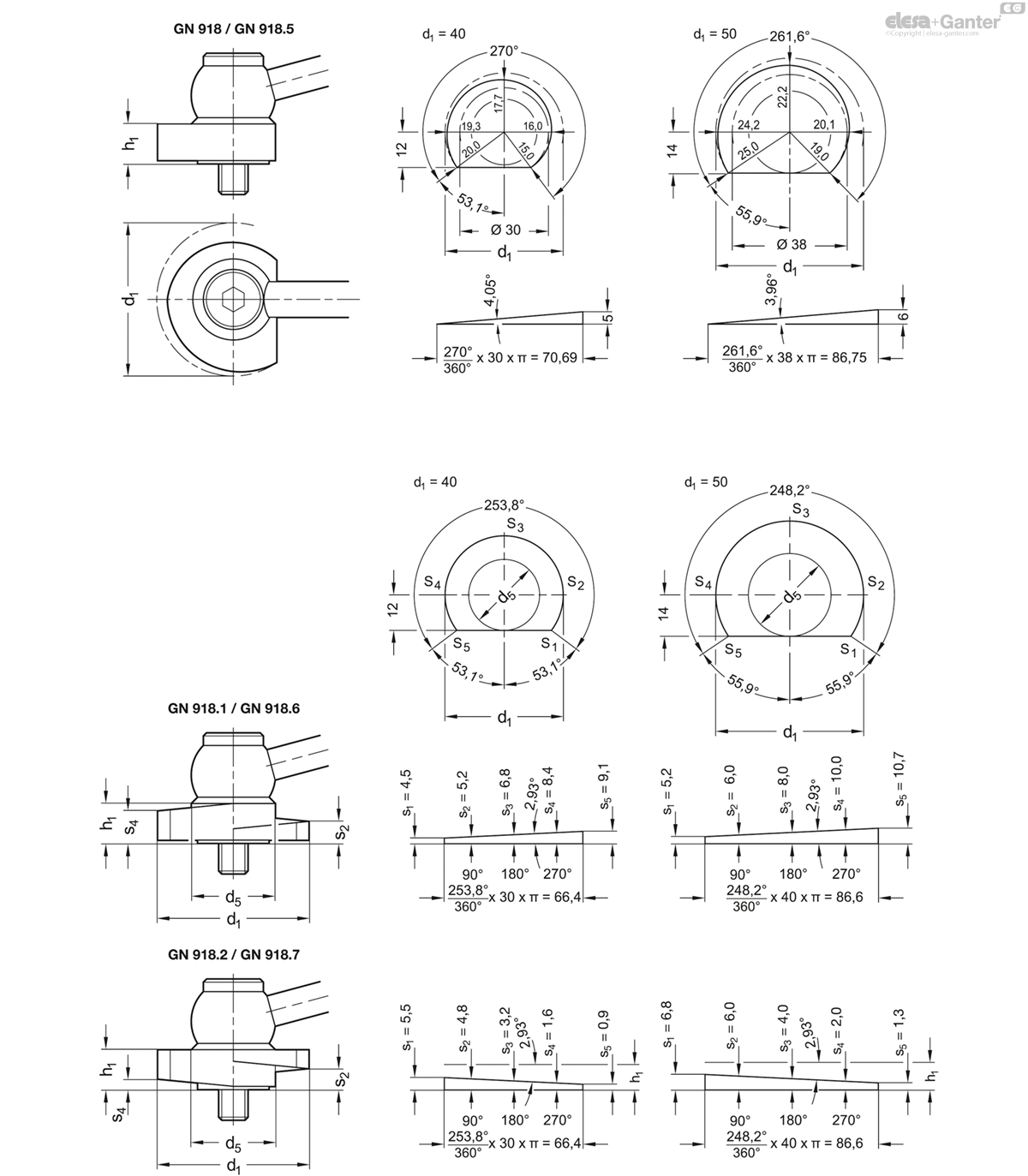

Clamping bolts GN 918.2 have a circumferential wedge surface. They allow for rapid and secure clamping and releasing with a relatively large clamping range and with high clamping force. Owing to the small pitch angle (wedge angle), the clamping bolt is self-locking. The ball levers of types KV / KVS / KVB and GV / GVS / GVB form a positive connection with the clamping bolt by means of a serration. During assembly, the lever can thus be fixed in a position favorable for clamping or, in the relaxed position, rotated out of the clamping range.

Version with Threaded Bolt

Use of the thrust washer eliminates the need for special requirements on the design of the threaded hole, which allows, for example, fastening to tables with T-slots.

Version with Screw from the Operator‘s Side

Fastening via screw from the operator‘s side bridges a greater clamping range. A sufficiently large screw-in depth t is necessary to safely absorb the screw forces.

Version with Screw from the Back

Fastening with a bushing allows the part to be used even if there is no thread in the surrounding structure. The heavy duty washer directs the resulting screw forces into the surrounding structure.

- Technical instructions

- Strength Values of Screws

- Plastic Characteristics

GN 918.2-SKS

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.