GN 820.1

Horizontal Acting Toggle Clamps

Description

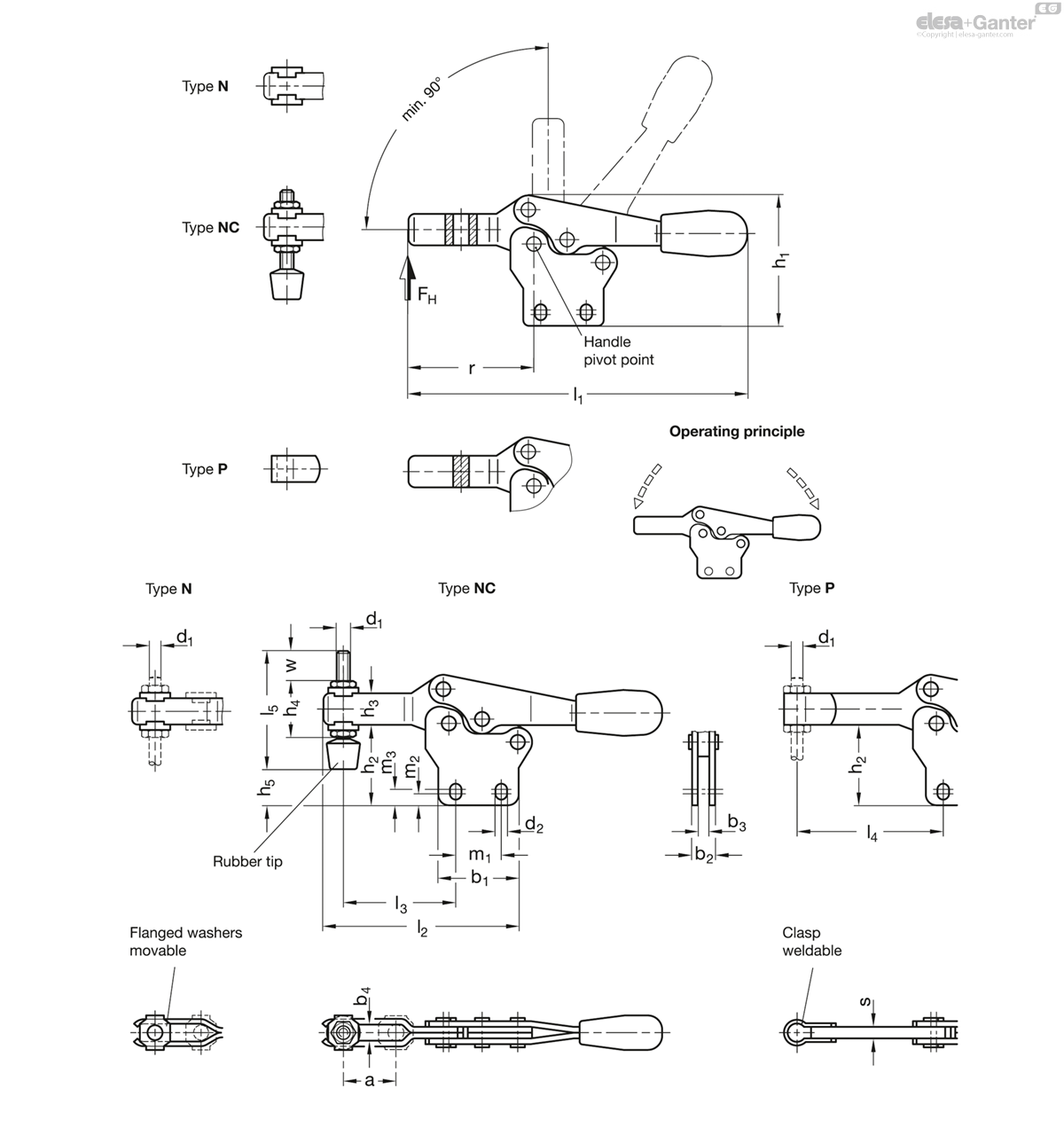

Types

- Type N: U-bar version, with two flanged washers

- Type NC: U-bar version, with two flanged washers and GN 708.1 spindle assembly

- Type P: Solid bar version, with clasp

Version in Steel

- Case-hardened Steel C10, zinc plated, blue passivated

- Bearing pins tempered

- Bearing rivets (for size 355 and up), case-hardened

All moving parts

lubricated with special grease

Hand grip

High quality, oil resistant red plastic

Spindle assembly GN 708.1, Type A

- Steel, zinc plated

- Rubber tip 85 Shore A

Version in Stainless Steel NI

Stainless Steel AISI 304

All moving parts

lubricated with special grease

Hand grip

High quality, oil resistant red plastic

Spindle assembly GN 708.1, Type A

- Stainless Steel AISI 304

- Rubber tip 85 Shore A

GN 820.1 horizontal acting toggle clamps work according to the toggle principle: lever and clamping bar move in the opposite direction.

They require less space for the clamping action. In the clamped position the operating lever is in its horizontal position.

Horizontal acting toggle clamps in the U-bar version with two flanged washers (Type N) can accommodate an application specific clamping screw. A spindle assembly with neoprene rubber tip is also included for Type NC.

Type P version can either be utilized by welding the clasp which can then accommodate an application specific hold-down fastener component, or by utilizing the bar in conjunction with the GN 809 clamp mounts to hold the work piece in place.

- General information for toggle clamps

- Stainless Steel characteristics

- Spindle assemblies

- GN 801 clamp mounts for toggle clamps (for Type N)

- GN 809 clamp mounts for toggle clamps (for Type P)

GN 820.1-NI

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.