GN 817.5

Indexing plungersDescription

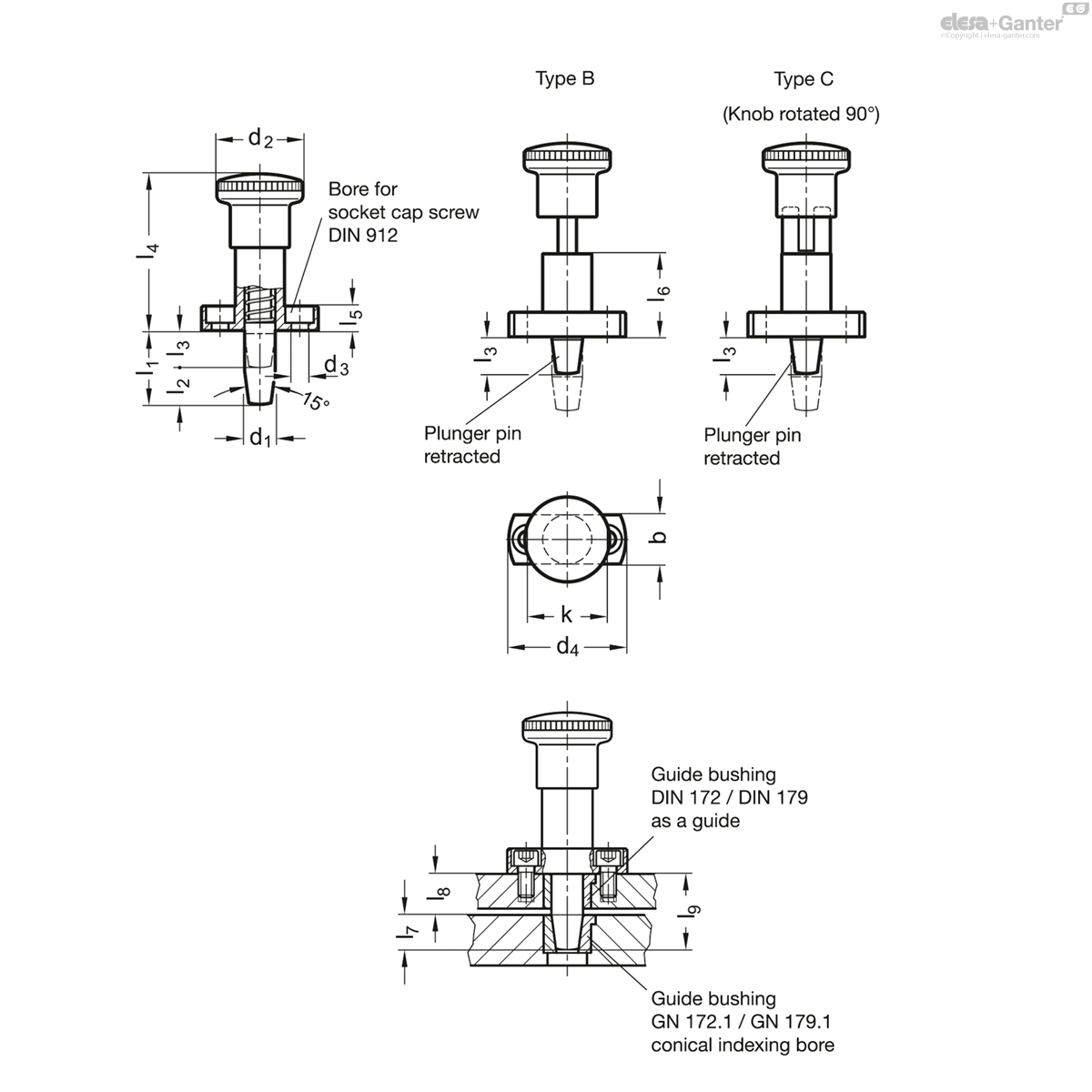

Types

- Type B: without rest position

- Type C: with rest position

Steel

- blackened

- Pin hardened and grounded

Knob Plastic (Polyamide PA)

- black, matt

- not removable

Indexing plungers GN 817.5 allow highly accurate positioning, with the guidance made by the positioning bushings DIN 172 / DIN 179 with cylindrical bore. The actual indexing bore is fitted with positioning bushings GN 172.1 / GN 179.1 with conical bores.

The conical shape of the indexing pin / the indexing bore makes the positioning virtually clearance-free and therefore highly precise.

Type C is used for such applications where the plunger has to stay in its retracted position. To achieve this, the knob is rotated by 90° degrees after being retracted. A notch keeps the plunger in this position.

- Range of indexing plungers

- ISO-Fundamental Tolerances

- Plastic characteristics

The length l7 is determined by the penetration depth of the indexing pin into the cone of the bushing.

The length l8 must ensure that the indexing pin fully disengages, bushing length and plate thickness olus any gap can then be selected within certain margins.

If engaged, the pin must have a minimum remaining stroke of 0.5 mm to make sure that the conical section of the pin is located without clearance in the cone of the guide bushing.

Two different plunger pin lengths l1 are available for each indexing plunger diameter d1 (see product table).

For a safe remaining stroke length: l9 = l1 - 0.5 mm

For mounting bushings with tolerance n6, a hole with tolerance H7 corresponding to the external diameter is usually provided.

A selection of suitable guide bushings DIN 172 and DIN 179 with cylindrical bore and guide bushings GN 172.1 / GN 179.1 with conical bore.

GN 817.5

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.