GN 808.3

Universal joint shafts with needle bearingDescription

Bore codes

- Version K: with keyway

Steel

blank

Joint bearing areas, pins

case hardened

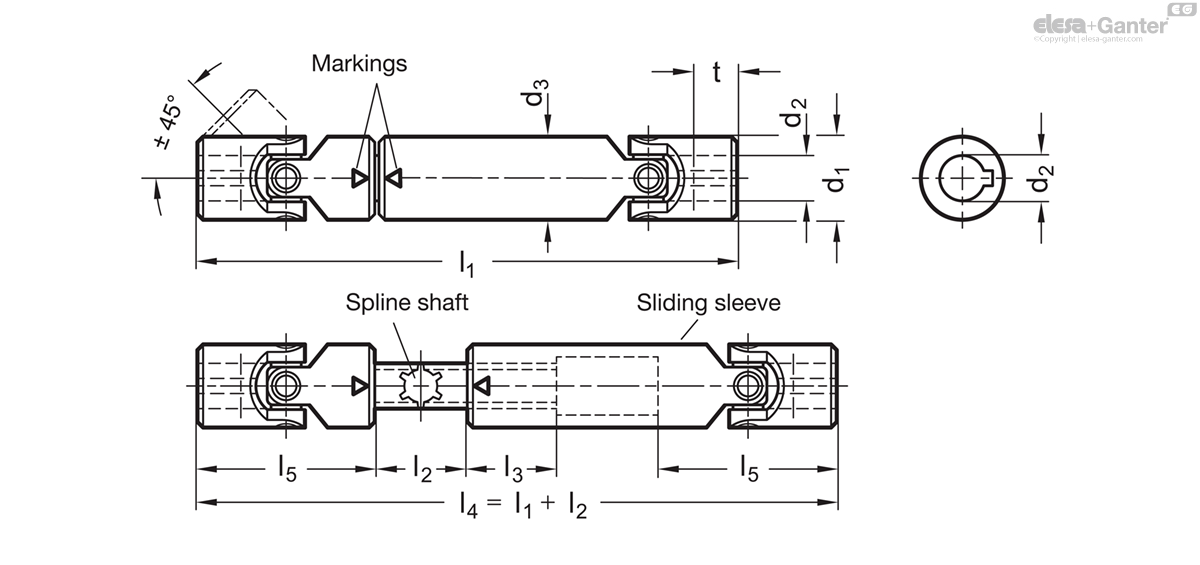

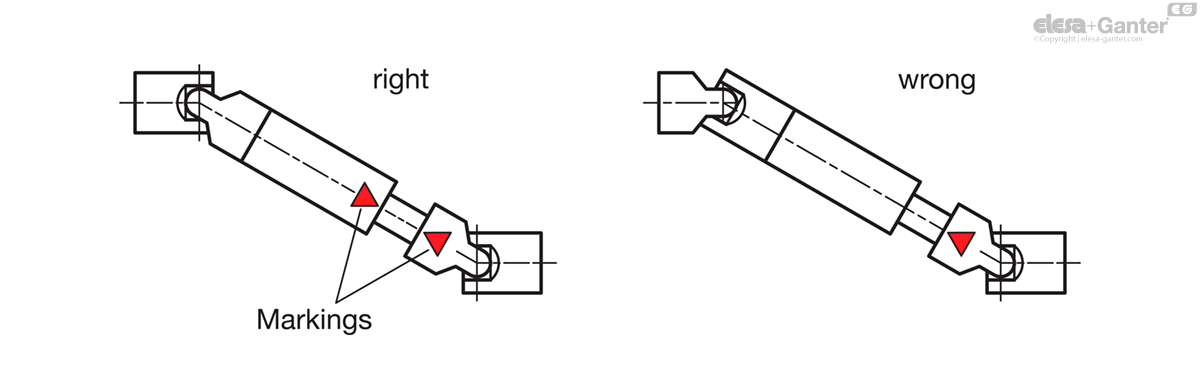

Universal joint shafts with needle bearing GN 808.3 not only join the offset between two shafts, but also enable the alignment of lengths, which depending on the overall length l1 enables the corresponding extraction length l2. The power transmission is achive-bed by two universal joints DIN 808 (type EW) a splined shaft and a sliding sleeve. It is important to check the accuracy when connecting the splined shaft to the sliding sleeve. The markings -> <- have to be opposite to each other. Any kind of misconnection leads to an inhomogeneous output and to a quick abrasion.

- different length l1 - l2

- Bores without keyway

- Bores with square

- Bores with hexagon

- with other or unequal bores

- Version in Stainless Steel (needle bearing not rustproof)

Permissible r.p.m. and torque

- Keyway DIN 6885

- Cross holes GN 110

- ISO-Fundamental Tolerances

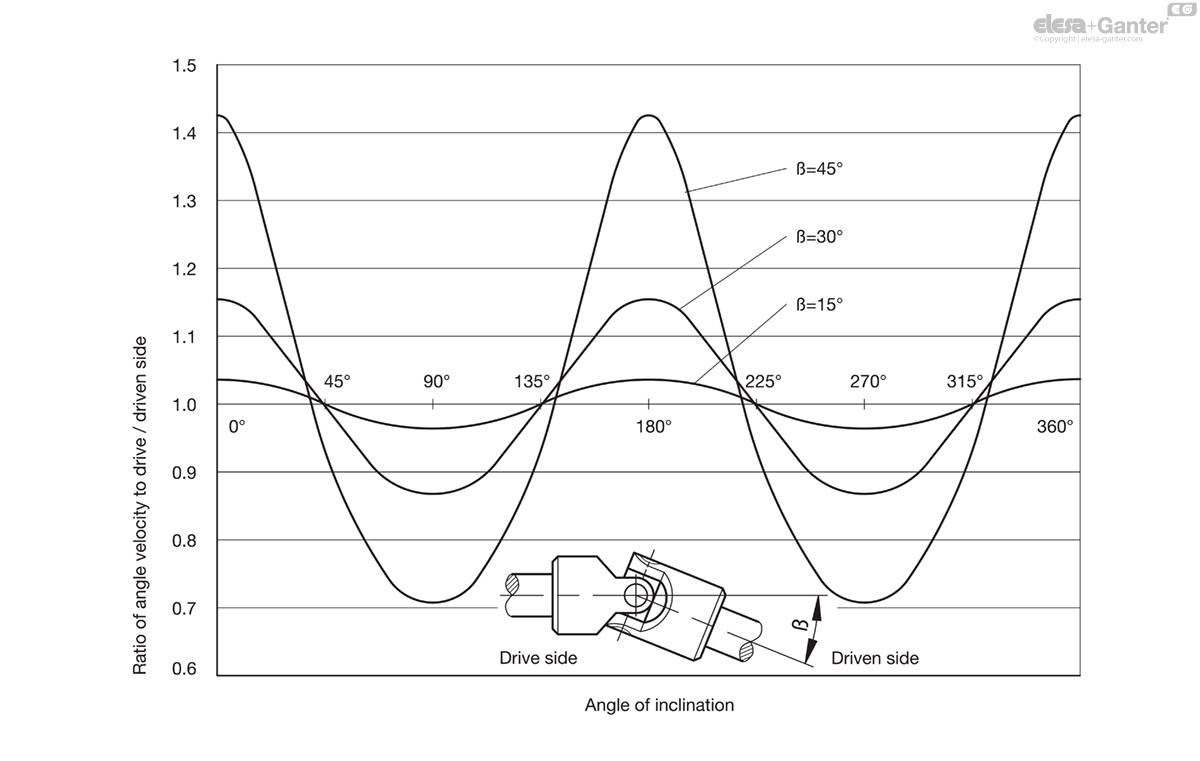

The single universal joints transfer the initial smooth rotation as an irregular rotation. One revolution of the drive shaft via single universal joint will cause the driven shaft to accelerate and decelerate twice. The extent of the irregularity depends on the operating angle ß.

In order to obtain a smooth rotation of the driven shaft two single or one double universal joint is required. In such cases where minor irregularities in the movement are acceptable or where minor operating angles are the norm a single universal joint will do.

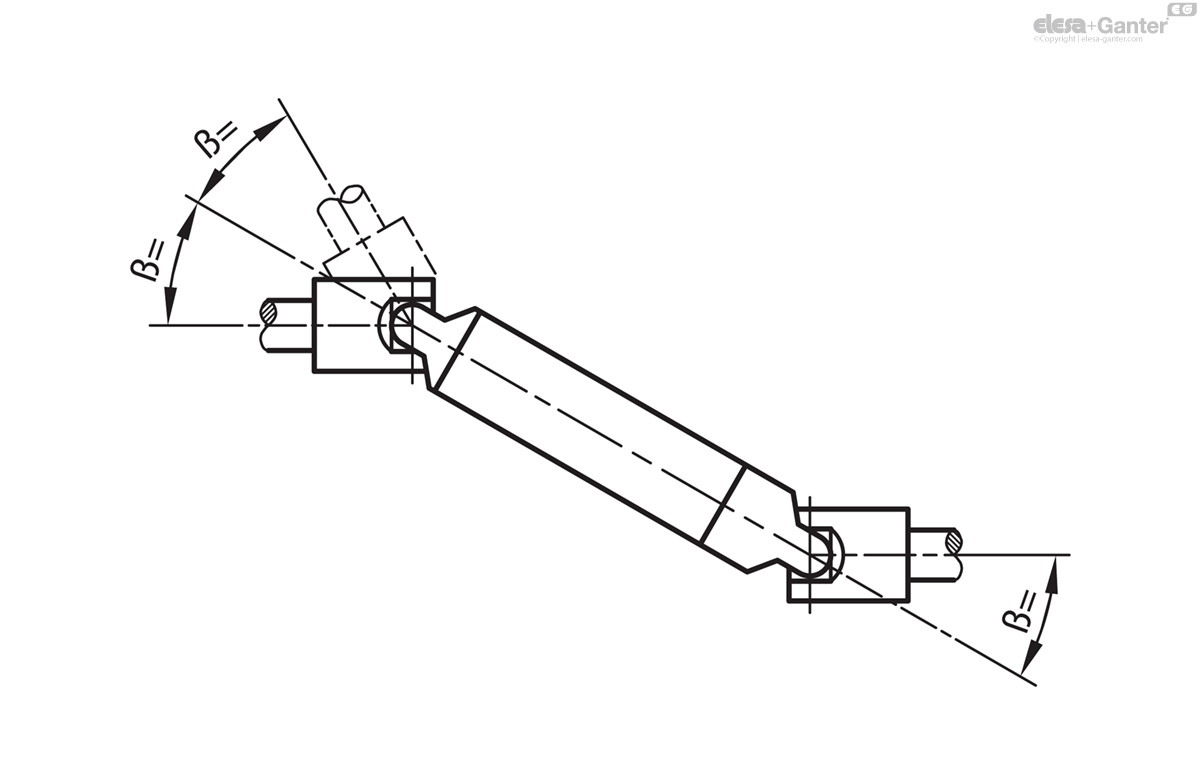

For a smooth transfer of a rotating speed, the angle of inclination ß must be equal at both ends of the connecting shaft.

Due to a misconnection of the universal joint shafts, the irregular rotation of each joint is not compensated, but strengthened. This allows joint bearings and wedge profiles to be destroyed. For this reason, the markings of the universal joint shaft halves have to be opposite to each other.

Furthermore the bearings must be as close as possible to the universal joints.

For continuous operation of universal joints with friction bearings adequate lubrication is essential. If drip lubrication is not possible they should be lubricated at least once a day. It is also possible to fit the universal joint with a gaiter GN 808.1 which can be filled with oil or grease.

Universal joints with needle bearing, Type EW

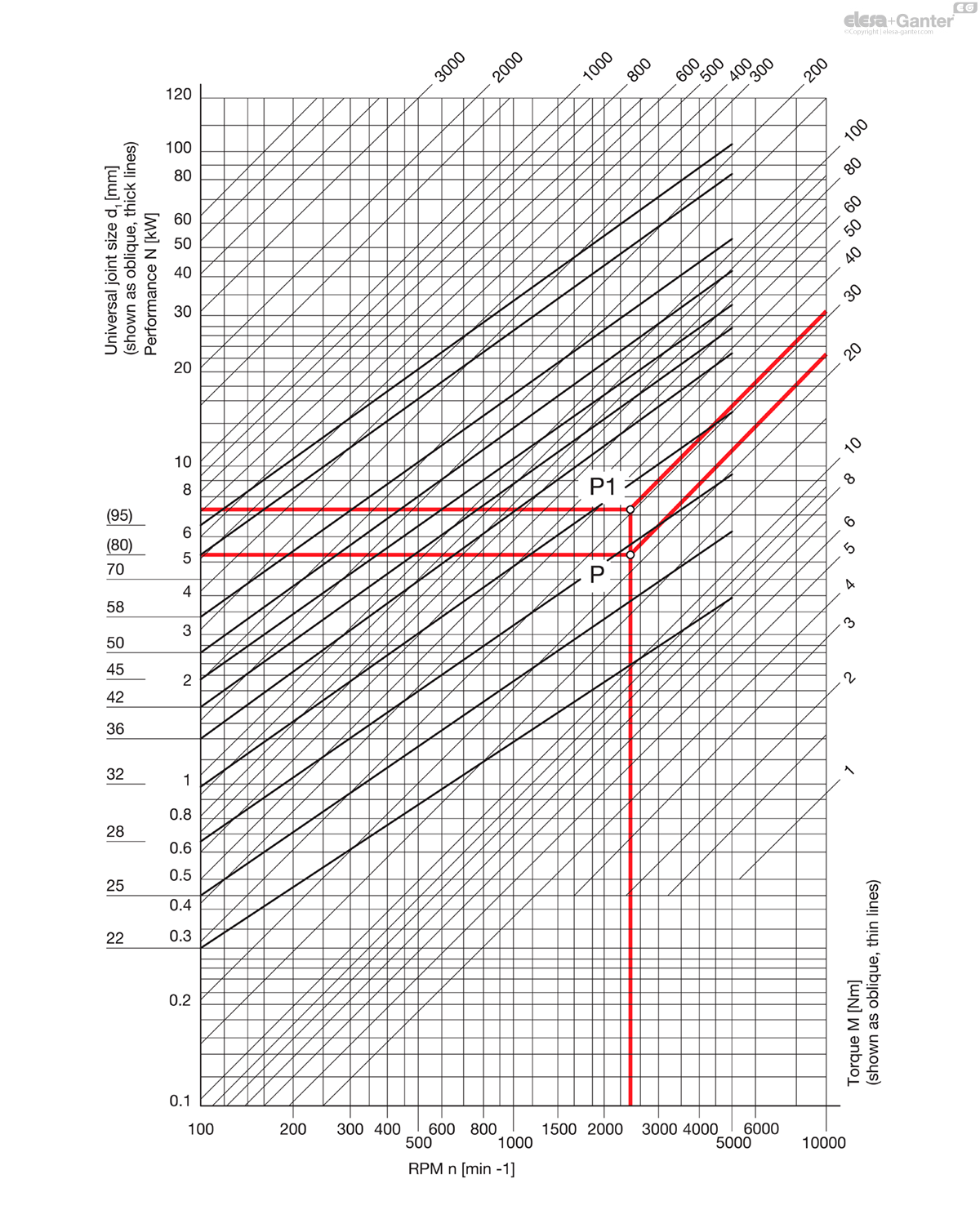

The table shows the transferable output N and/or torques M of universal joints DIN 808, type EW (single needle bearing) in relation to the RPM n.

The values are only applicable to a constant speed of rotation, constant load and an operating inclination angle of max. 10°.

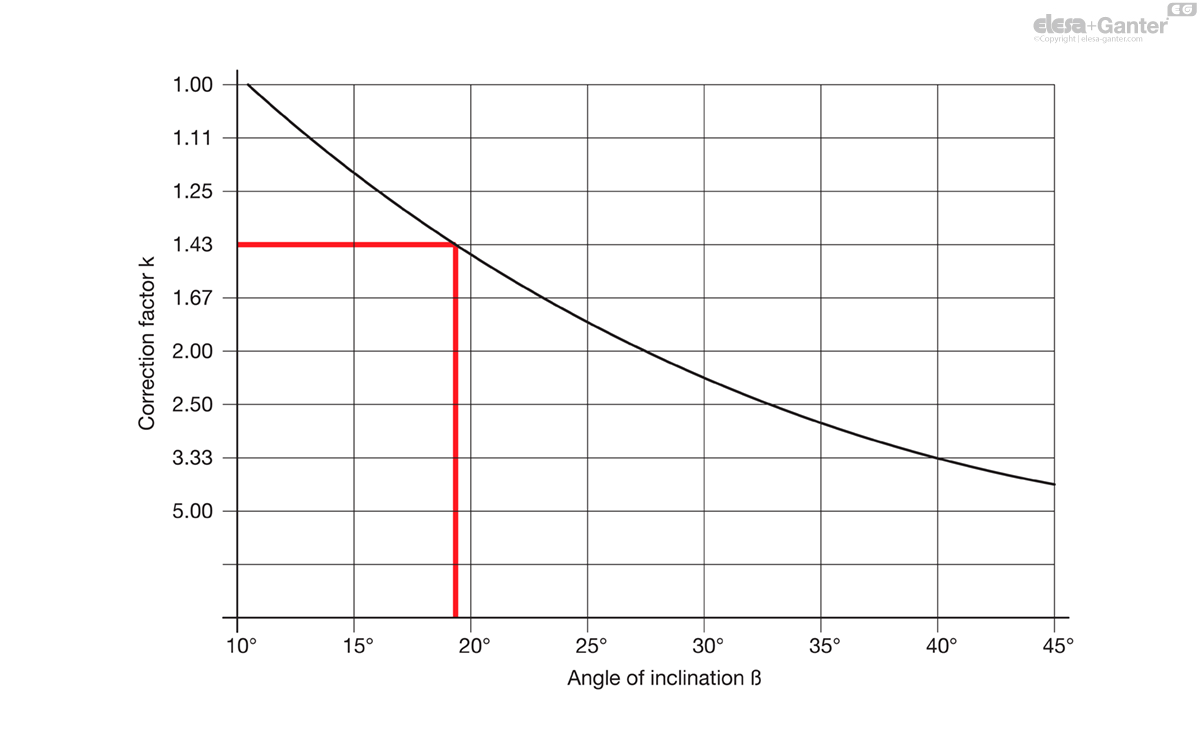

For larger inclination angles ß a nominal output N increased by the correction coefficient k and/or a nominal torque M has to be selected (see example below).

Conversion formular:

Torque M [Nm] = 9550 N[kW]/n [min-1]

Output N [kW] = M [Nm] x n [min-1]

1 kW = 1.36 PS / 1 PS = 0.736 kW

Example 1

Torque to be transferred N = 5.5 kW

R.p.m. n = 2300 min-1

Angle of inclination ß = 10°

Correction coefficient k = 1

Indicative output N = Nominal output N

Intersection point P is arrived at from 5.5 kW and 2300 min-1 (which corresponds to a torque of 23 Nm).

The next size up universal joint corresponding to point P is the model with a diameter d1 = 28.

Example 2

Torque to be transferred M = 23 Nm

R.p.m. n = 2300 min-1

Angle of inclination ß = 18°

Correction coefficient k = 1.43

Indicative torque = 1.43 x 23 Nm = 33 Nm

Intersection point P1 is arrived at from 33 Nm and 2300 min-1 (which is equivalent to an indicative output N = 7.9 kW).

The next size up universal joint corresponding to P1 is the model with a diameter d1 = 32.

GN 808.3

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.