GN 713

Side Thrust Pins

Description

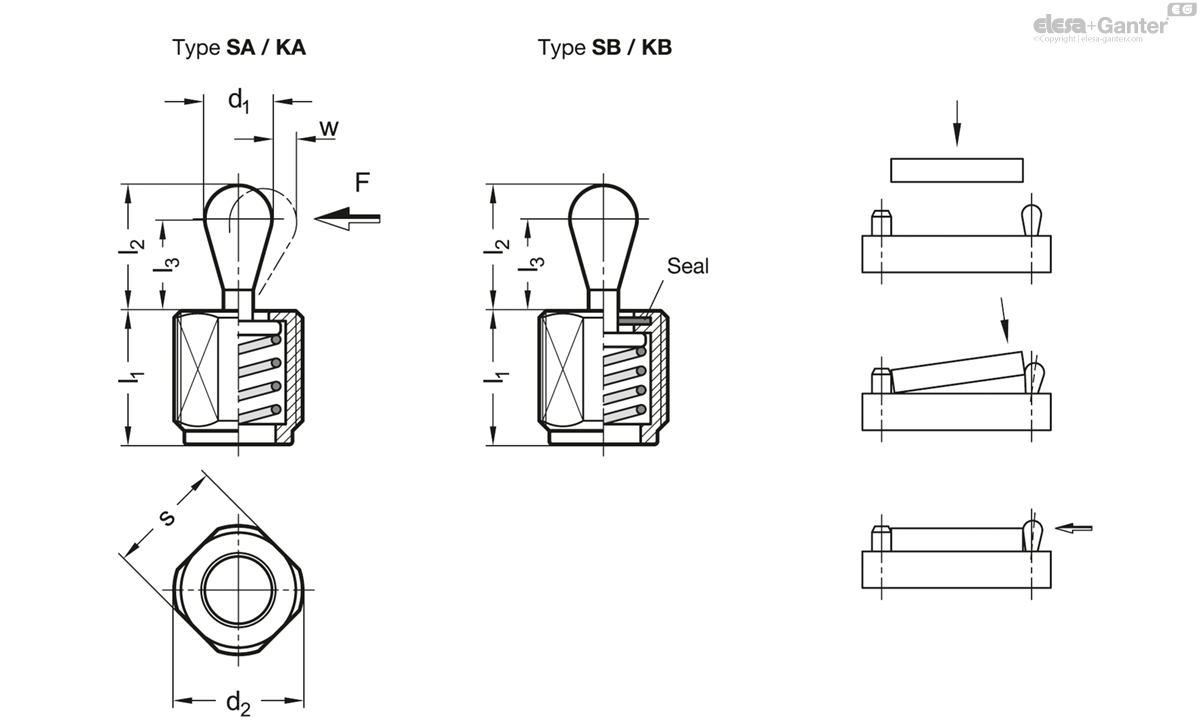

Types

- Type SA: Thrust pin steel, without seal

- Type KA: Thrust pin plastic, without seal

- Type SB: Thrust pin steel, with seal

- Type KB: Thrust pin plastic, with seal

Housing

Steel

Zinc plated, blue passivated

Thrust pin

- Steel for SA / SB

- Hardened

- Zinc plated, blue passivated

- Plastic, Polyacetal (POM) for KA / KB

Thrust spring

- Side thrust force light

- Stainless steel AISI 301

- Side thrust force medium

- Spring steel blackened

- Side thrust force heavy

- Spring steel zinc plated, blue passivated

Seal

Chloroprene rubber (CR)

Spring loaded side thrust pins GN 713 are versatile and practical elements for holding, positioning and clamping workpieces.

They eliminate costly alternatives, are space saving and simple to install. The protruding height of the thrust pin can be adjusted with the threaded body.

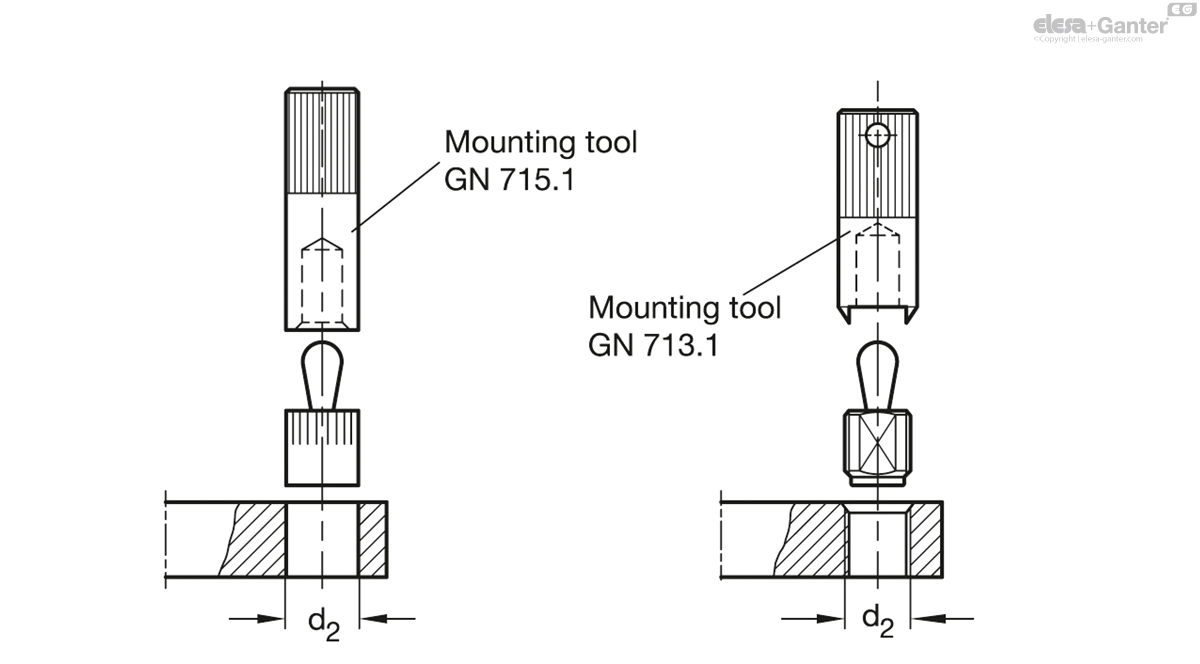

For mounting the side thrust pins a suitable mounting tool GN 713.1 is available (see table).

- GN 713.1 Mounting Tools (Code no. see table)

- Plastic Characteristics

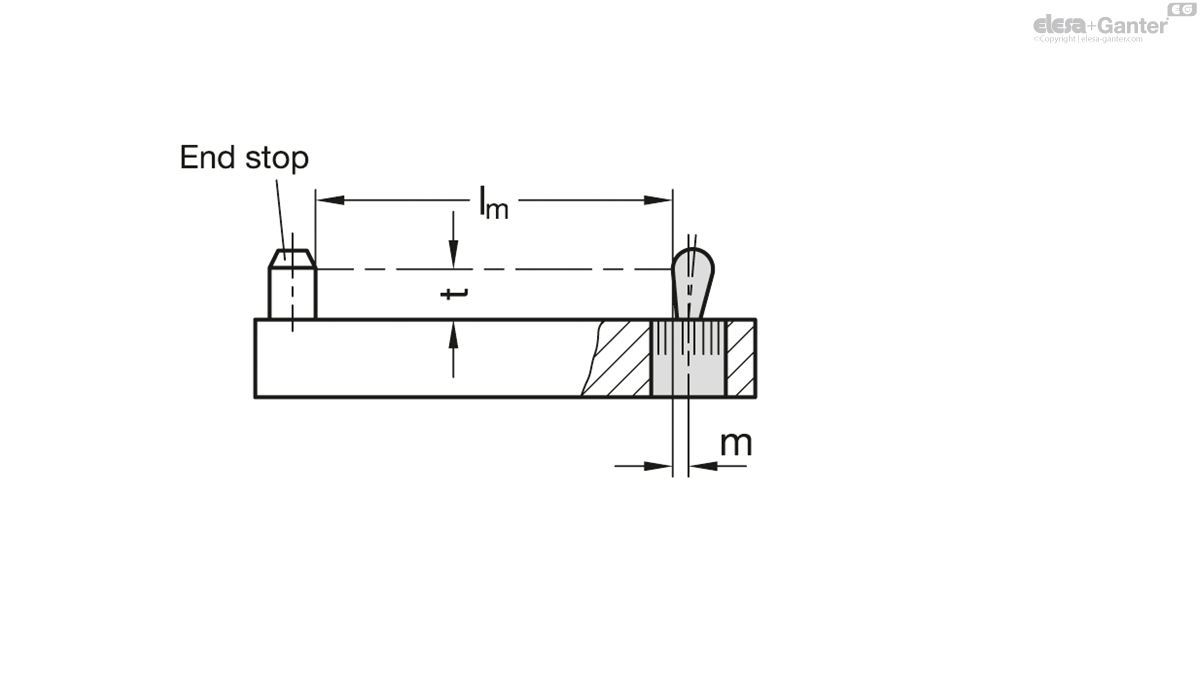

The position of the mounting hole results from the workpiece length lm plus the hole offset m, which is calculated as shown below:

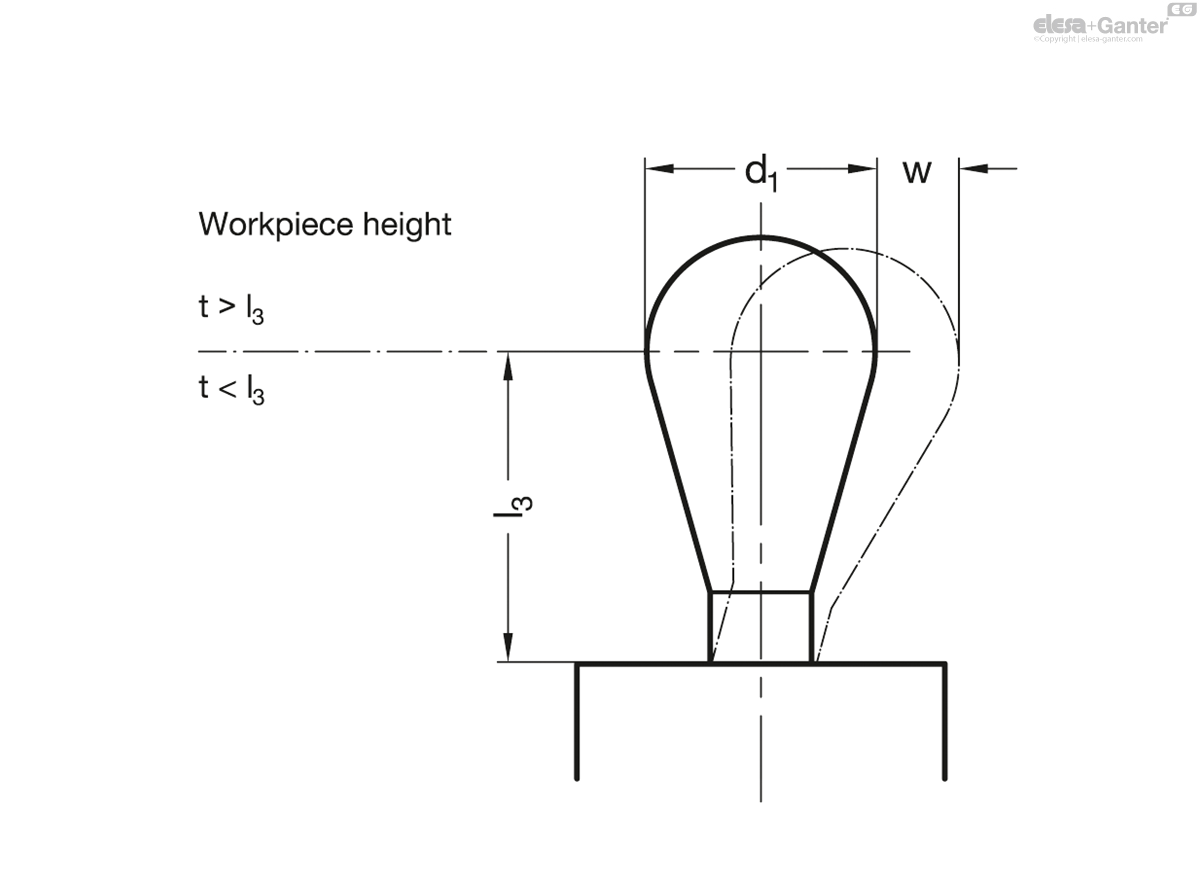

w = Maximum movement range of the thrust pin

t = Workpiece height

m = Hole offset

Case 1:

The workpiece height t is greater than the cone height l3

m = d1/2 - w/2

Case 2:

The workpiece height t is greater than the cone height l3

m = d1/2 - (l3-t) x 0,123

If the position of the mounting hole is determined as specified, the full movement of the side thrust pin will be available to cover the tolerance of the workpiece.

In case 1, the lateral clamping force is coupled with a downward pull that presses the workpiece against the contact surface.

The use of a mounting tool GN 715.1 or mounting tool GN 713.1 is recommended for installation.

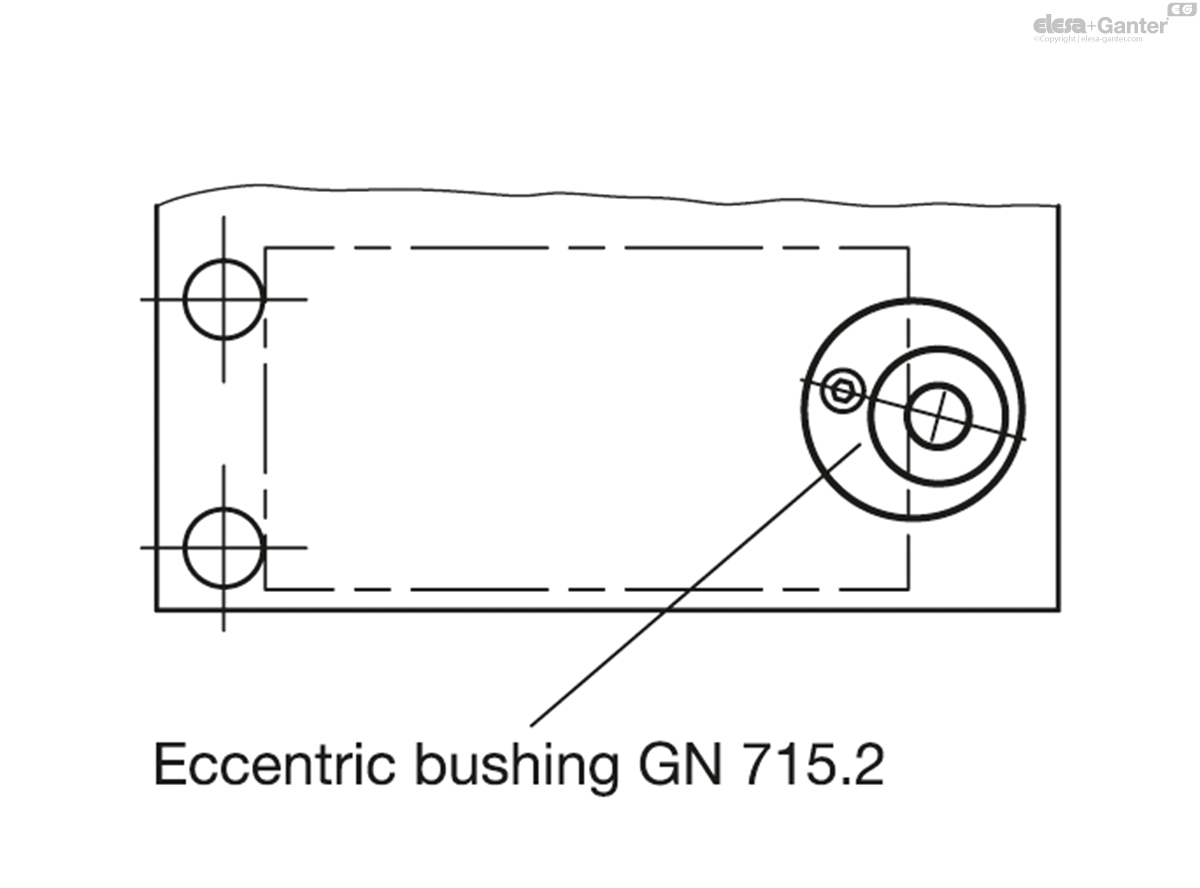

Eccentric bushings GN 715.2 are an assembly aid for side thrust pins GN 714 / GN 715. They enable adjustment of the side thrust pins to the most favorable clamping position, e.g. to bridge larger tolerance ranges of a workpiece.

GN 713-KA

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.