GN 587.1

Load RingsDescription

Types

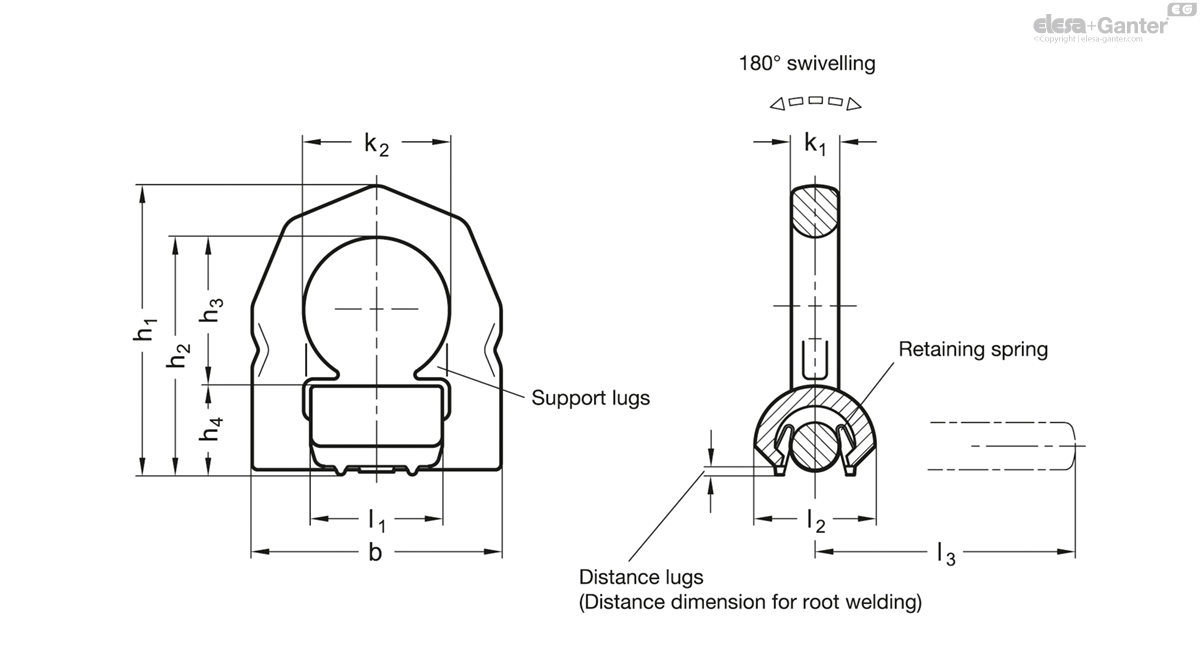

- Type A: without retaining spring

- Type F: with retaining spring

Ring brackets

Steel, German Material No. 1.6541

- forged

- high-tensile tempered

- 100 % electro magnetic tensile tested to EN 1677

- plastic coated, pink

Weld-on block

Steel, S355 J2 + N (ST52-3N)

- forged, blank

- high-tensile tempered

- 100 % electro magnetic tensile tested to EN 1677

Retaining spring

Stainless Steel tape

rustproof

Load rings GN 587.1 for welding are designed for rapid mounting.

They provide high dynamic and static strength and can be load from any direction with approved safety (safety factor 4) for all loading directions.

The spring steel tape (Type F) holds the ring in any position and dampens any noise caused by vibrations. All parts are undetachably connected.

The two support lugs improve the bearing of hooks and enhance the support effect in the event of oblique suspension rings.

Load rings GN 587.1 comply with Mechanical Engineering Directive 2006 / 42 / EG.

This standard replaces the previous load rings GN 587.

- Operating instructions GN 587.1

| Method of mounting | ||||||||||

| Number | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 3 and 4 | 3 and 4 | 3 and 4 |

| Angles of inclination | 0° | 90° | 0° | 90° | 0° to 45 | 45° to 60° | asymm. | 0° to 45° | 45° to 60° | asymm. |

| Factor | 1 | 1 | 2 | 2 | 1.4 | 1 | 1 | 2.1 | 1.5 | 1 |

| b = 66 | 1.50 t | 1.50 t | 3.00 t | 3.00 t | 2.10 t | 1.50 t | 1.50 t | 3.15 t | 2.25 t | 1.50 t |

| b = 77 | 2.50 t | 2.50 t | 5.00 t | 5.00 t | 3.50 t | 2.50 t | 2.50 t | 5.25 t | 3.75 t | 2.50 t |

| b = 87 | 4.00 t | 4.00 t | 8.00 t | 8.00 t | 5.60 t | 4.00 t | 4.00 t | 8.40 t | 6.00 t | 4.00 t |

| b = 115 | 6.70 t | 6.70 t | 13.40 t | 13.40 t | 9.50 t | 6.70 t | 6.70 t | 14.00 t | 10.00 t | 6.70 t |

| b = 129 | 10.00 t | 10.00 t | 20.00 t | 20.00 t | 14.00 t | 10.00 t | 10.00 t | 21.00 t | 15.00 t | 10.00 t |

The above details refer to the maximum load in metric tonnes.

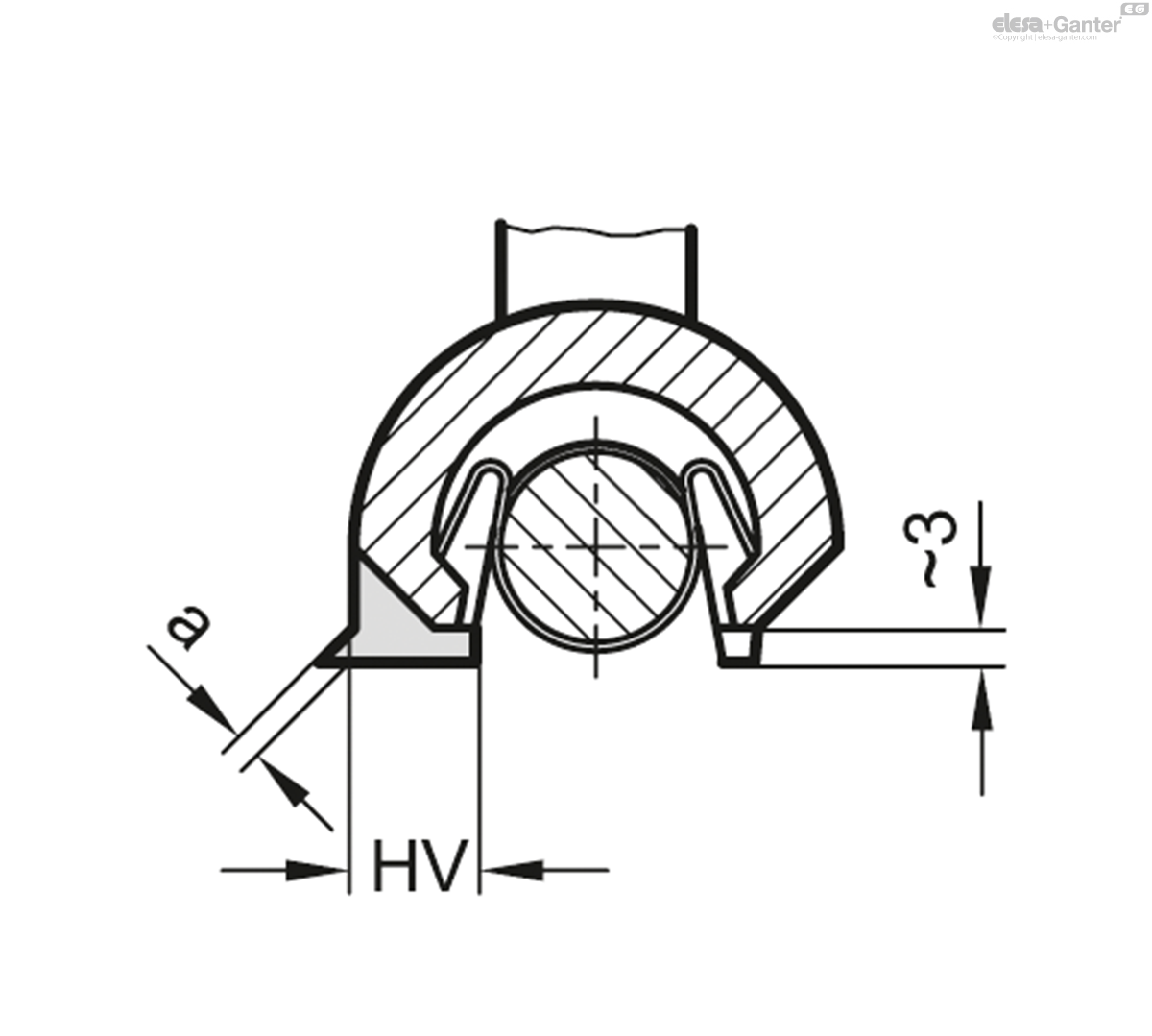

The configuration of the welding seam (HV) complies with the requirements of DIN 18800, i. e., the closed seam means that no corrosive deposits can settle; this also makes the load rings suitable for outside use.

| Loading ring size | Size Welding seam | Length | Volume in cm3 |

| b = 66 ( 1.5 t) | HV 5 + a 3 | 2 x 33 | 1.2 |

| b = 77 ( 2.5 t) | HV 7 + a 3 | 2 x 40 | 2.6 |

| b = 87 ( 4.0 t) | HV 8 + a 3 | 2 x 46 | 3.2 |

| b = 115 ( 6.7 t) | HV 12 + a 4 | 2x 60 | 8.7 |

| b = 129 ( 10.0 t) | HV 16 + a 4 | 2x 60 | 15.5 |

Welding must be made by an approved welder in accordance with EN 287-1.

The specified loading values are valid for an operating temperature of between –20 °C and +100 °C. Load capacities under higher temperatures provided on request.

If the load rings are used for lashing instead of lifting, the nominal load is doubled.

Operating instructions with more details and specifications are included with every delivery.

GN 587.1

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.