GN 581.5

Lifting Eye Bolts (Rotating)Description

Ring

Stainless steel AISI 318LN

- Forged

- 100% electro magnetic tensile test to EN1677

- Plain

Bolt

Stainless steel AISI 318LN

Lifting eye bolts GN 581.5 are mounted in rotating bearings, allowing the direction of the force action to be adjusted and preventing inadvertent loosening or overturning (as potentially possible in lifting eye bolts DIN 580). Lifting eye bolts GN 581.5 offer a high load carrying capacity and they are tested to meet safety standards (safety factor 4).

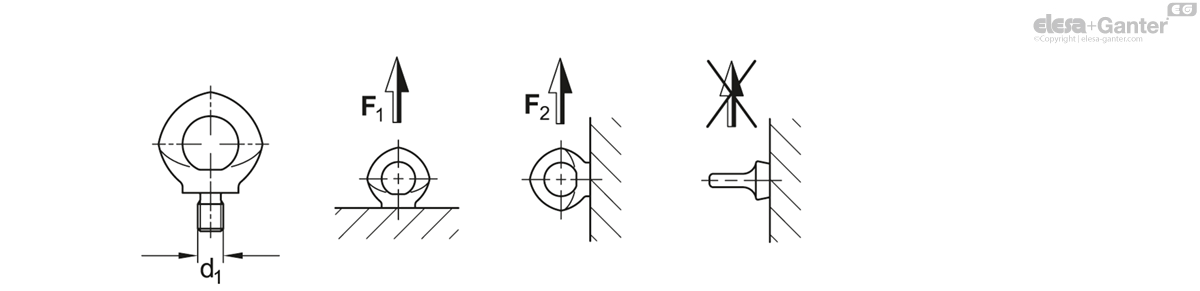

The rated load carrying capacity listed in the above table is clearly marked on the ring. It applies to the most unfavourable load application of the load types listed opposite.

Lifting eye bolts GN 581.5 eye bolts comply with Mechanical Engineering Directive 2006 / 42 / EG and are BG tested.

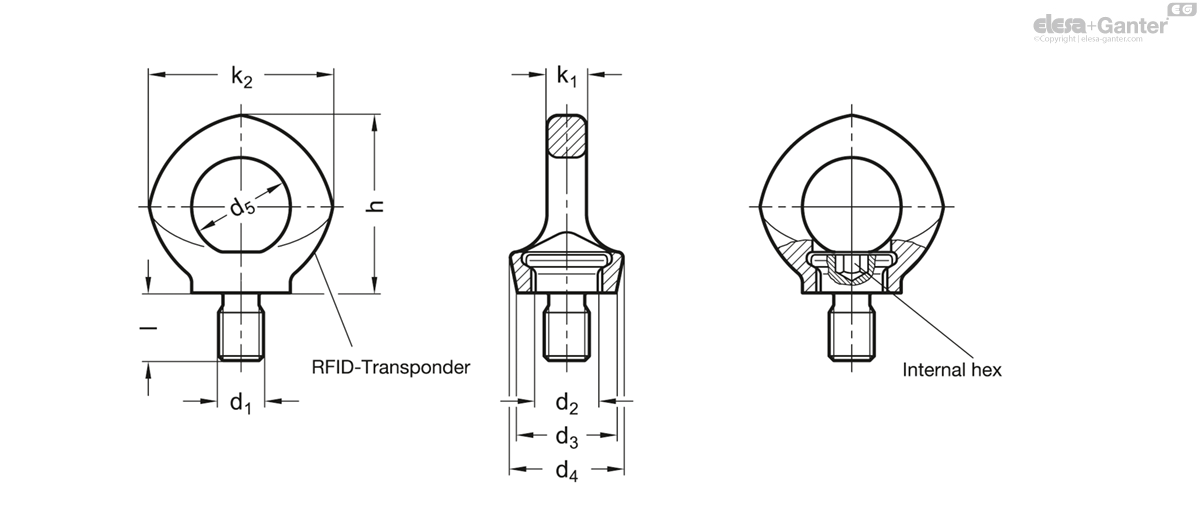

The integrated RFID transponder clearly marks and identifies the lifting point, e.g. during the prescribed regular inspection.

The hex socket bolt cannot be removed from the ring.

- Stainless Steel Characteristics

| d1 | F1 max. in t | F2 max. in t |

| M 8 | 0.7 [0.14] | 0.3 |

| M 10 | 0.7 [0.23] | 0.3 |

| M 12 | 1.2 [0.34] | 0.5 |

| M 16 | 2.4 [0.7] | 1 |

| M 20 | 3.6 [1.2] | 2 |

| M 24 | 5.2 [1.8] | 2.5 |

The loads given in brackets refer to the load capacity of the corresponding lifting eye bolts DIN 580. If such a value is not indicated the use of the lifting eye bolts DIN 580 is not permitted!

The bolt-on surface for the lifting eye bolts GN 581.5 must be plane and at a right angle to the threaded borehole; the countersinking must be ≤ the nominal diameter of the thread.

Screwed in, the collar of the screw must make firm contact (do not use washers) and the eye bolt must rotate freely by 360°.

Before applying the load, turn the lifting eye bolt in the direction of the force. The lifting eye bolt is not suitable for frequent rotation cycles under load.

The specified load values apply for a minimum screw-in length of 1,5 × nominal thread diameter in stainless steel with a minimum tensile strength of 37 kp/mm², at an ambient temperature of – 40° C to + 280° C. Load-bearing capacity under different conditions upon request.

The operating instruction contains further guidelines and is included with every lifting eye bolt.

GN 581.5

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.