GN 24

Leveling Feet

Description

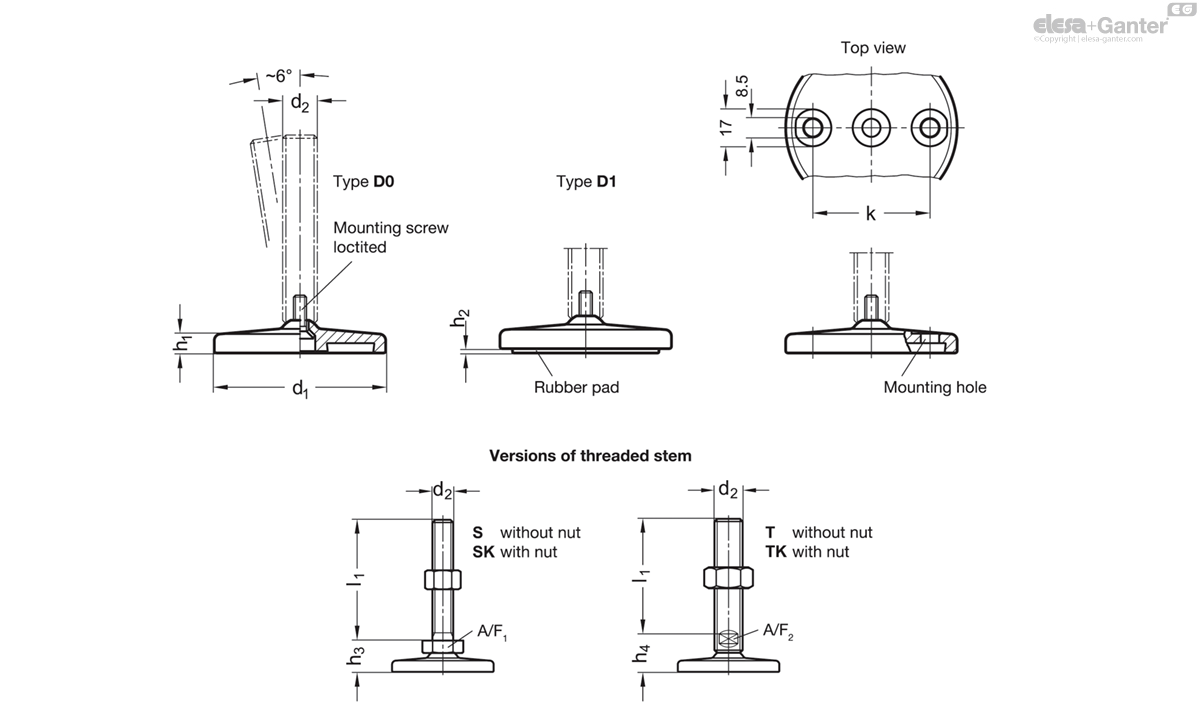

Type (Base plate)

- Type D0: Fine turned, without rubber underlay

- Type D1: Fine turned, with rubber underlay, inlaid, black

Versions of threaded stem

- Version S: Without nut, external hex at the bottom

- Version SK: With nut, external hex at the bottom

- Version T: Without nut, wrench flat at the bottom

- Version TK: With nut, wrench flat at the bottom

Base plate

Stainless steel AISI 316L

Threaded stem

Stainless steel AISI 316L

Hex nuts ISO 4032

Stainless steel

Mounting screw

Stainless steel

Rubber underlay

Acrylonitrile butadiene rubber (NBR)

- Black

- Hardness 70 Shore A

- Inserted

Leveling feet GN 24 are particularly suitable for use in aggressive environments.

The leveling feet are supplied assembled and cannot be disassembled.

- Plastic Characteristics

- Stainless Steel Characteristics

| d1 | d2 | Static load in kN | ||||

| - | - | Versions of threaded stem | ||||

| - | - | S / SK | T / TK and U / UK | V / VK | W | X |

| 80 | M 8 | 6 | - | - | - | 17 |

| 80 | M 10 | 11 | - | - | - | 17 |

| 80 | M 12 | 16 | - | - | - | 17 |

| 80 | M 16 | - | 17 | 21 | 25 | 17 |

| 80 | M 20 | - | 28 | 35 | 35 | 28 |

| 80 | M 24 | - | 46 | 52 | 52 | - |

| 100 | M 8 | 6 | - | - | - | 17 |

| 100 | M 10 | 11 | - | - | - | 17 |

| 100 | M 12 | 16 | - | - | - | 17 |

| 100 | M 16 | - | 17 | 21 | 25 | 17 |

| 100 | M 20 | - | 28 | 35 | 35 | 28 |

| 100 | M 24 | - | 46 | 52 | 52 | - |

| 120 | M 20 | - | 28 | - | - | 28 |

| 120 | M 24 | - | 46 | - | - | - |

| 120 | M 30 | - | 43 | - | - | - |

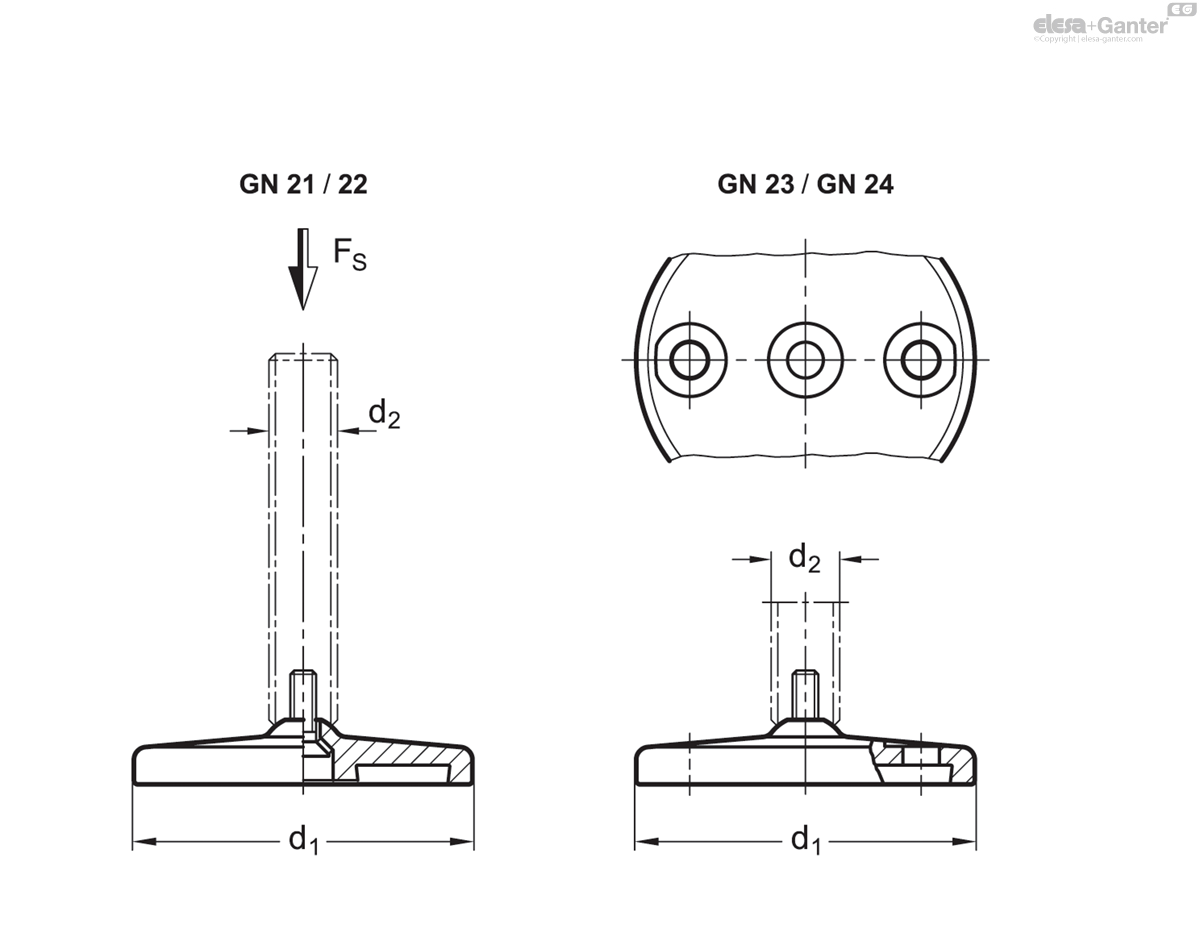

At a spindle thread size M 10 and higher, the static load of the leveling feet GN 21 / GN 22 / GN 23 / GN 24 is limited owing to the permissible contact pressure of the adjustment spindle acting on the base plate (at a spindle strength ≥ 500 N/mm2). The values given in the table (valid for type D0 without rubber underlay) assume a clean pressure load perpendicular to the base plate. Bending and buckling stress which often occurs in practice results in a lower load-bearing capacity of the adjustment spindle and may have to be taken into account.

The details given on strength are non-binding guide values without any liability. In general, they do not constitute a warranty or quality.

The user must determine from case to case if a product is suitable for the intended purpose or use. Environmental factors may influence the stated values.

| Versions of threaded stem | |

| S: Without nut | T: Without nut |

| SK: With nut | TK: With nut |

| External hex at the bottom at d2 M 8, M 10, M 12 | Wrench flat at the bottom d2 M 16, M 20, M 24, M 30 |

GN 24-S

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.