GN 17

Leveling Feet

Description

Type (Base plate)

- Type C3: Polished, rubber vulcanized, black

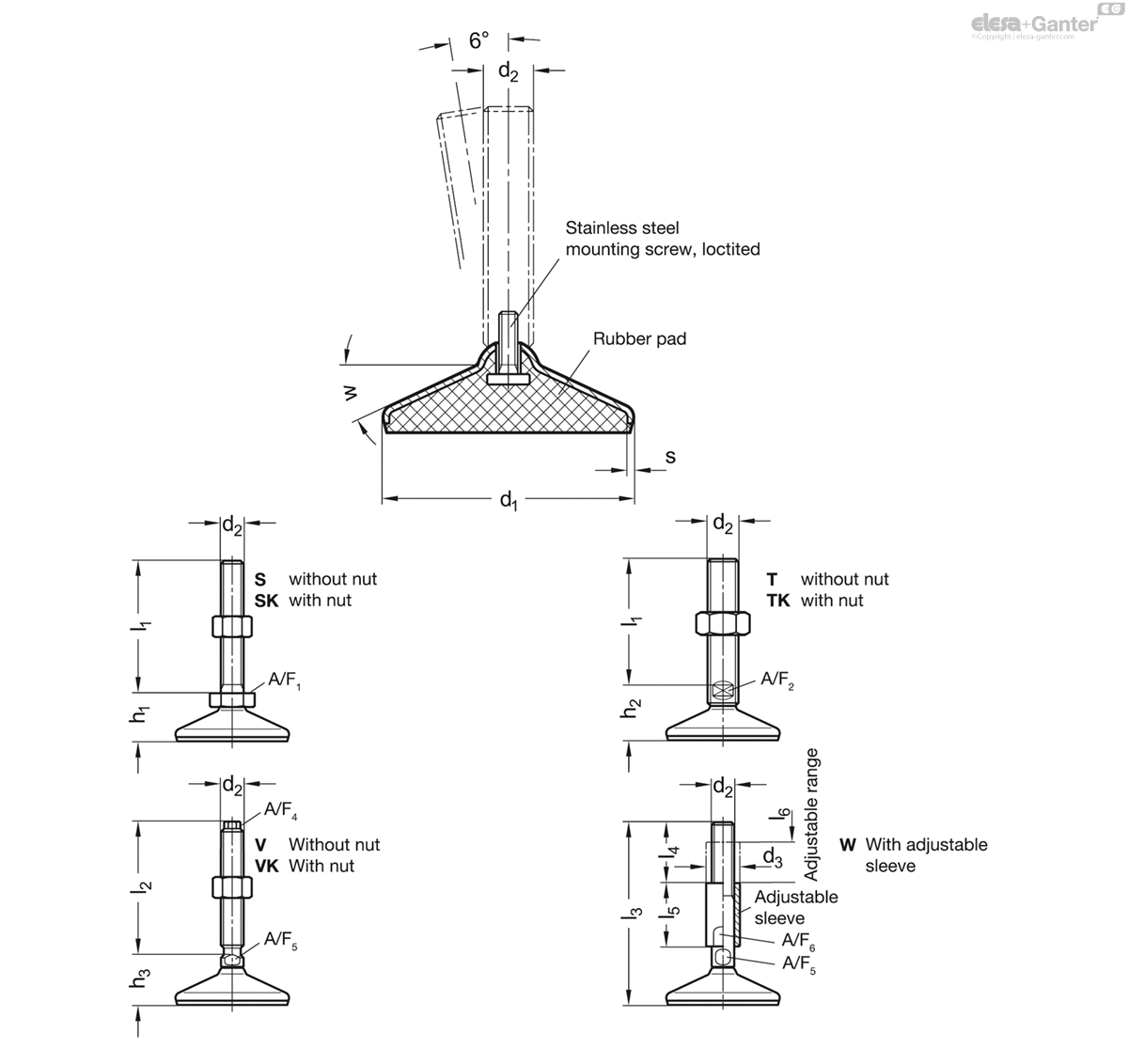

Versions of threaded studs

- Version S: Without nut, external hex at the bottom

- Version SK: With nut, external hex at the bottom

- Version T: Without nut, wrench flat at the bottom

- Version TK: With nut, wrench flat at the bottom

- Version V : Without nut, external hex at the top and wrench flat at the bottom

- Version VK: With nut, external hex at the top and wrench flat at the bottom

- Version W: With adjustable sleeve, covered thread and wrench flat at the bottom

Base plate

Stainless steel AISI 304

Threaded stud

Stainless steel AISI 303

Hex nut ISO 4032

Stainless steel AISI 304

Rubber pad

Acrylonitrile butadiene rubber (NBR)

- Black

- FDA-compliant

- Hardness 85±5 Shore A

- Vulcanized

Leveling feet GN 17 are suitable for use in aggressive environments.

The inclined surfaces for liquid runoff and the high surface quality of the base plate simplify cleaning and prevent the accumulation of dust or dirt. The FDA-compliant and vulcanized rubber underlay seals the base against the resting surface and allows the feet to be used in food-processing areas or the pharmaceutical industry, for example.

The leveling feet are supplied assembled and cannot be disassembled.

- Rubber pad available in various colors

- Plastic Characteristics

- Stainless Steel Characteristics

| d1 | d2 | Static load Fs in kN | - | - | - |

| - | - | Versions of threaded studs | - | - | - |

| - | - | S / SK | T / TK | V / VK | W |

| 60 | M 8 | 8 | - | - | - |

| 60 | M 10 | 8 | - | - | - |

| 60 | M 12 | 14 | - | - | - |

| 60 | M 16 | - | 14 | 14 | 14 |

| 80 | M 8 | 8 | - | - | - |

| 80 | M 10 | 8 | - | - | - |

| 80 | M 12 | 14 | - | - | - |

| 80 | M 16 | - | 14 | 14 | 14 |

| 80 | M 20 | - | 32 | 32 | 32 |

| 80 | M 24 | - | 36 | 36 | 36 |

| 100 | M 8 | 8 | - | - | - |

| 100 | M 10 | 8 | - | - | - |

| 100 | M 12 | 16 | - | - | - |

| 100 | M 16 | - | 24 | 24 | 24 |

| 100 | M 20 | - | 26 | 26 | 26 |

| 100 | M 24 | - | 28 | 28 | 28 |

| 120 | M 20 | - | 26 | - | - |

| 120 | M 24 | - | 26 | - | - |

| 120 | M 30 | - | 26 | - | - |

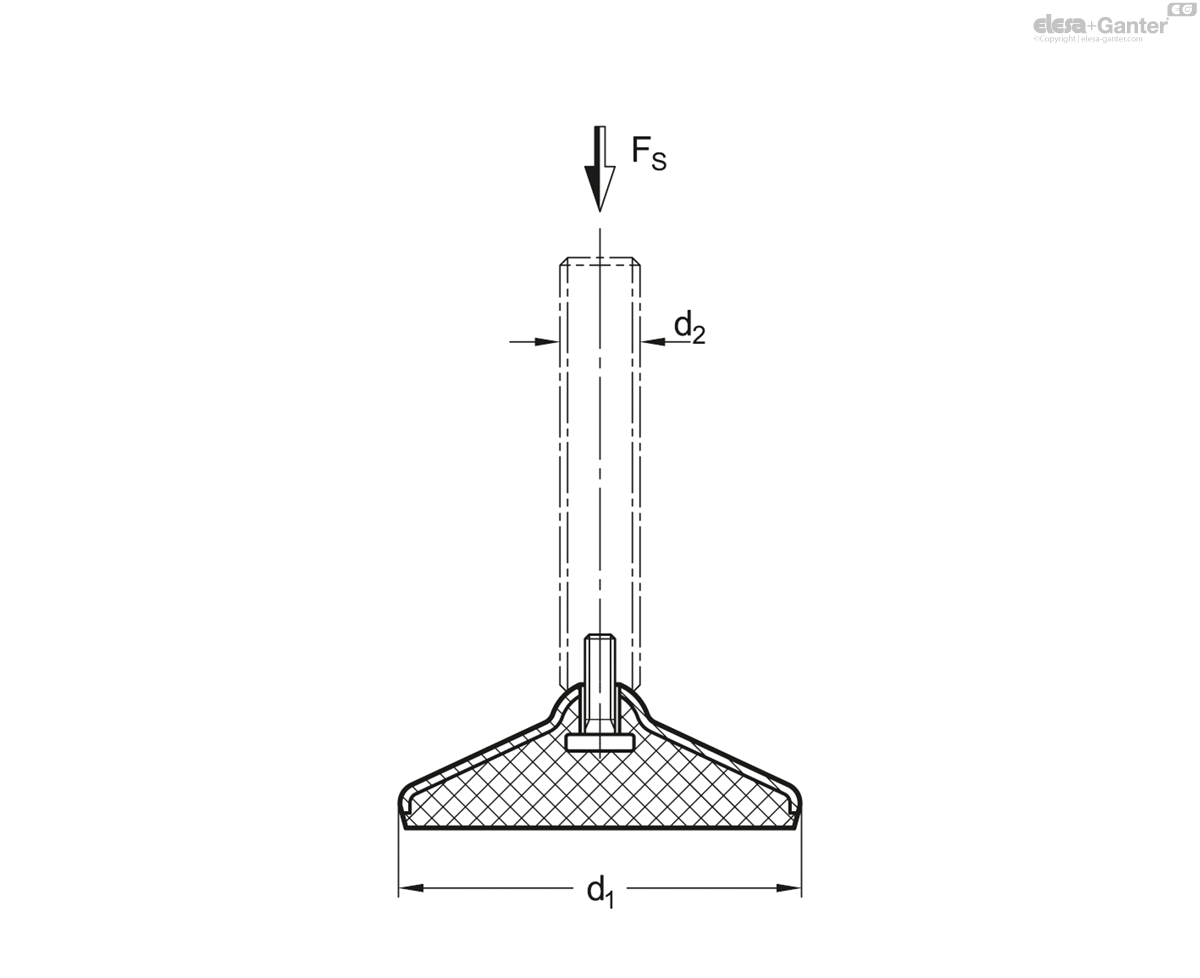

The static load bearing capacity given in the table rests on a test series in which the load has been applied perpendicular to the base plate (without rubber underlay). For the values given in the table, the strain relief may result in minor deformations of the base plate.

Bending and buckling stress which often occurs in practice results in a lower load bearing capacity of the adjustment spindle and may have to be taken into account.

Also, the spindle strength is assumed to be ≥ 500 N/mm2).

The details given on strength are non binding guide values without any liability. In general, they do not constitute a warranty of quality.

The user must determine from case to case if a product is suitable for the intended purpose or use. Environmental factors may influence the stated values.

| Versions of threaded studs | |

| S / SK: External hex at the bottom at d2 M 8, M 10, M 12 | T / TK: Wrench flat at the bottom at d2 M 16, M 20, M 24, M 30 |

| V / VK: External hex at the top and wrench flat at the bottom at d2 M 16, M 20, M 24 | W: Covered thread and wrench flat at the bottom at d2 M 16, M 20, M 24 |

GN 17-V/VK

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.