GN 115-WOE-SST

Latches

Description

Version with Plastic Operating Elements

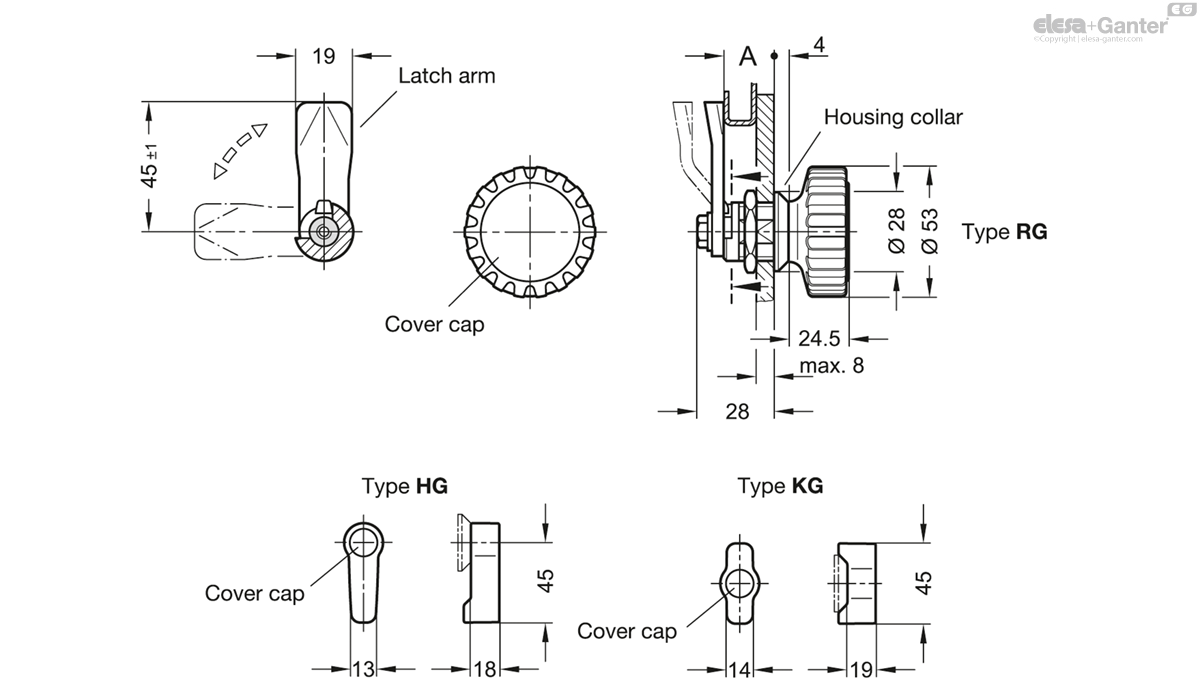

Types

- Type RG: With knurled knob GN 7336

- Type KG: With wing knob

- Type HG: With lever

Lock housing

Stainless steel AISI 303 NI

Latch arm

Stainless steel AISI 304

Operating elements

Plastic (Polyamide PA)

Black, matte finish

Other parts

Stainless steel AISI 304

Protection class IP 65

Version with Operating Elements in Stainless Steel (NI)

Types

- Type SG: With star knob

- Type KGN: With wing knob

- Type HGN: With lever

- Type SKN: With wing knob

- Type STN: With T-handle

Lock housing NI

- Type SG, KGN, HGN

- Stainless steel AISI 303

- Type SKN, STN

- Stainless steel AISI 316

Latch arm

Stainless steel AISI 304

Operating elements

- Type SG

- Stainless steel AISI 304

- Sheet metal drawn and hub welded

- Type KGN, HGN

- Stainless steel AISI CF-8

- Type SKN, STN

- Stainless steel AISI 316

Other parts

Stainless steel AISI 304

Protection class IP 65

Version with Operating Elements in Stainless Steel (A4)

Types

- Type SKN: With wing knob

- Type STN: With T-handle

Lock housing / Operating Elements A4

Stainless steel AISI 316

Latch arm

Stainless steel AISI 316

Other parts

Stainless steel AISI 316

Protection class IP 65

Latches GN 115-WOE-SST lock by a turning operation limited to 90° which moves the latch arm in the locked position behind the door frame. The bevels of the latch arm ease the closing of the door. Thanks to the stainless steel materials used, the latches are optimally suited for use in corrosive environments.

Latch arms are available with different bend angles to cover a latch arm distance A from 6 to 50 mm and from 6 to 28 mm (version A4).

Latches GN 115-WOE-SST are supplied with loosely enclosed latch arm.

- Protective Guide Plates GN 120.2

- Internal Cabinet Handles GN 120.3

- Sheet Metal Punches GN 123

- List of latch types

- ISO-Fundamental Tolerances

- IP Protection Classes

- Plastic Characteristics

- Stainless Steel Characteristics

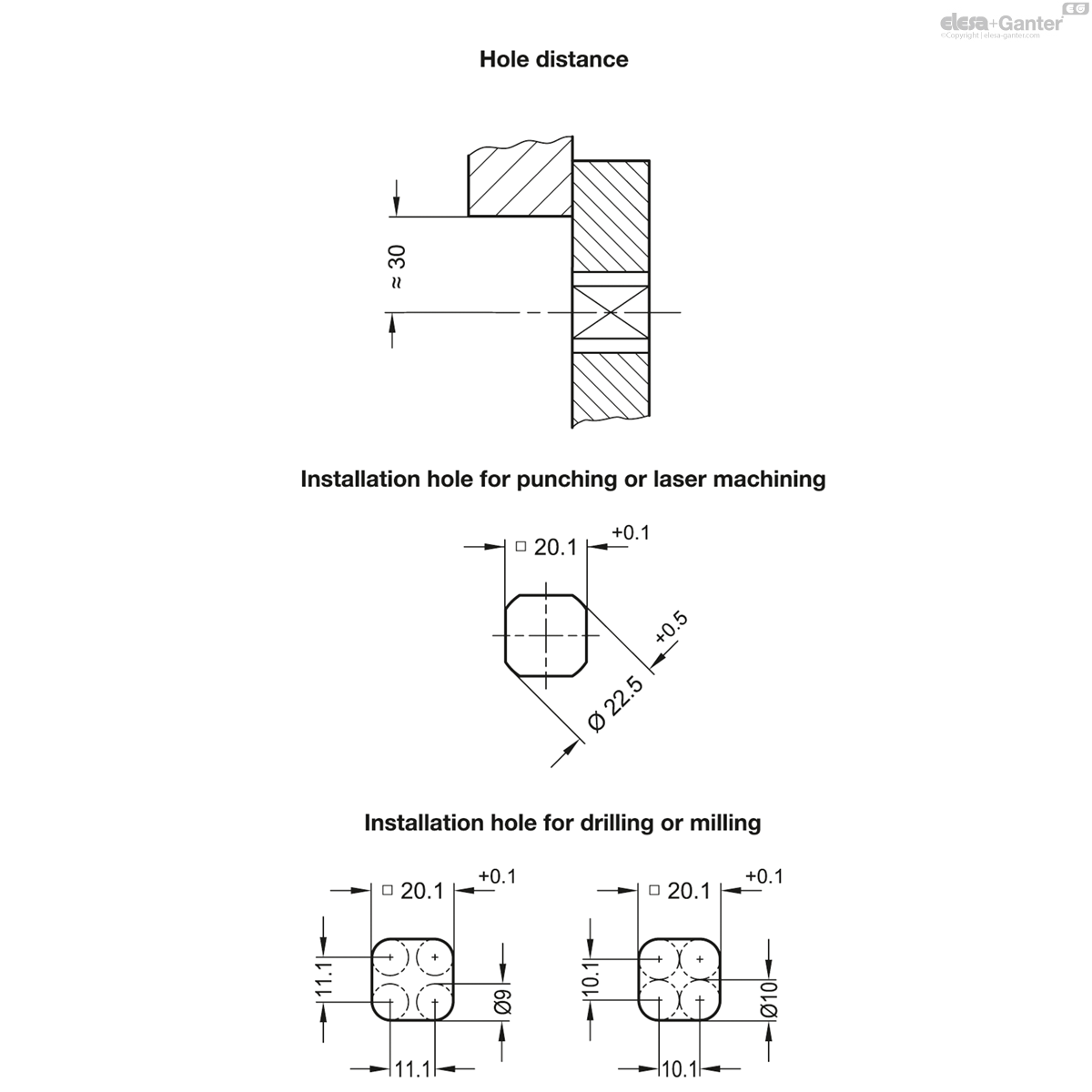

For installation, set a hole in the door, cover or hatch as shown in the outline drawing.

Once assembled, the latch is pushed through the bore diameter from the front. The hex nut can then be pushed over the latch from the back and bolted in place.

The required installation bore in the door leaf, is usually generated by punching or laser machining in series production.

The installation bore diameter can also be created by drilling or milling as shown in the outline drawings.

For small series and steel sheets below 2 mm thickness, the sheet metal punches GN 123 are the tool of choice.

GN 115-WOE-SST-PA

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.