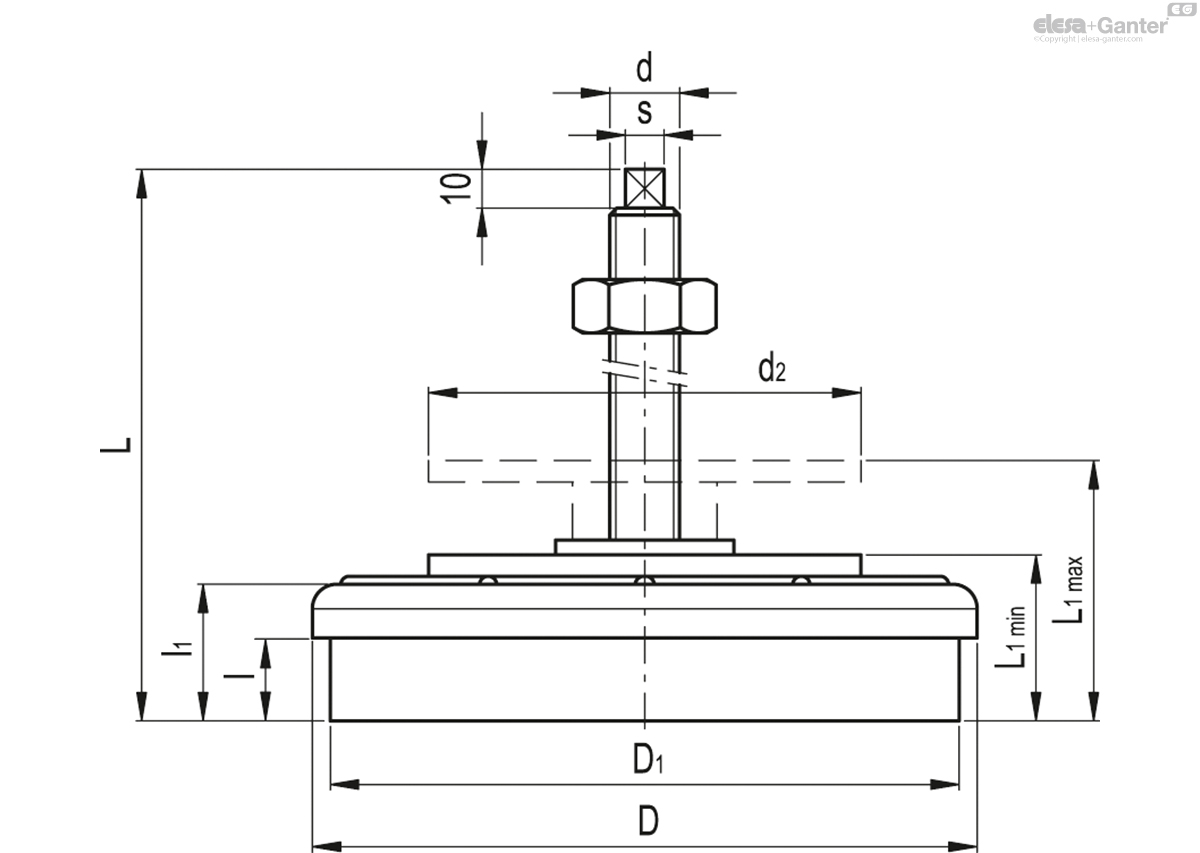

LW.A

Vibration-damping levelling elements

Steel base and stem

Description

Main specifications

Base

Zinc-plated steel.

Damping element

NR rubber, hardness 80 Shore A, black colour, matte finish.

Levelling plate

Zinc-plated steel.

Packing ring

NBR synthetic rubber O-Ring.

Threaded stem

Zinc-plated steel, supplied not assembled.

Nut and washer

Zinc-plated steel.

General information

Features

ELESA vibration-damping levelling elements have been designed to damp vibrations, shocks and noises produced by moving bodies or non-balanced vibrating masses of equipment and machines which can cause:

- malfunctioning and reduction of the machine lifespan and/or of the adjacent ones;

- damage to operator's health;

- noise.

Technical data and guidelines for the choice

- Basic data required:

- disturbing frequency: the frequency of the disturbing vibration produced by a on-duty machine. In general, it is obtained by the number of rotations of the engine [Hz=r.p.m./60];

- the load applied to every single vibration-damping element [N];

- the isolation degree required [%];

- the deflection value of the vibration-damping element under a given load [mm];

- the rigidity, that is to say the load that applied to the vibration-damping element produces a deflection of 1.0 mm [N/mm].

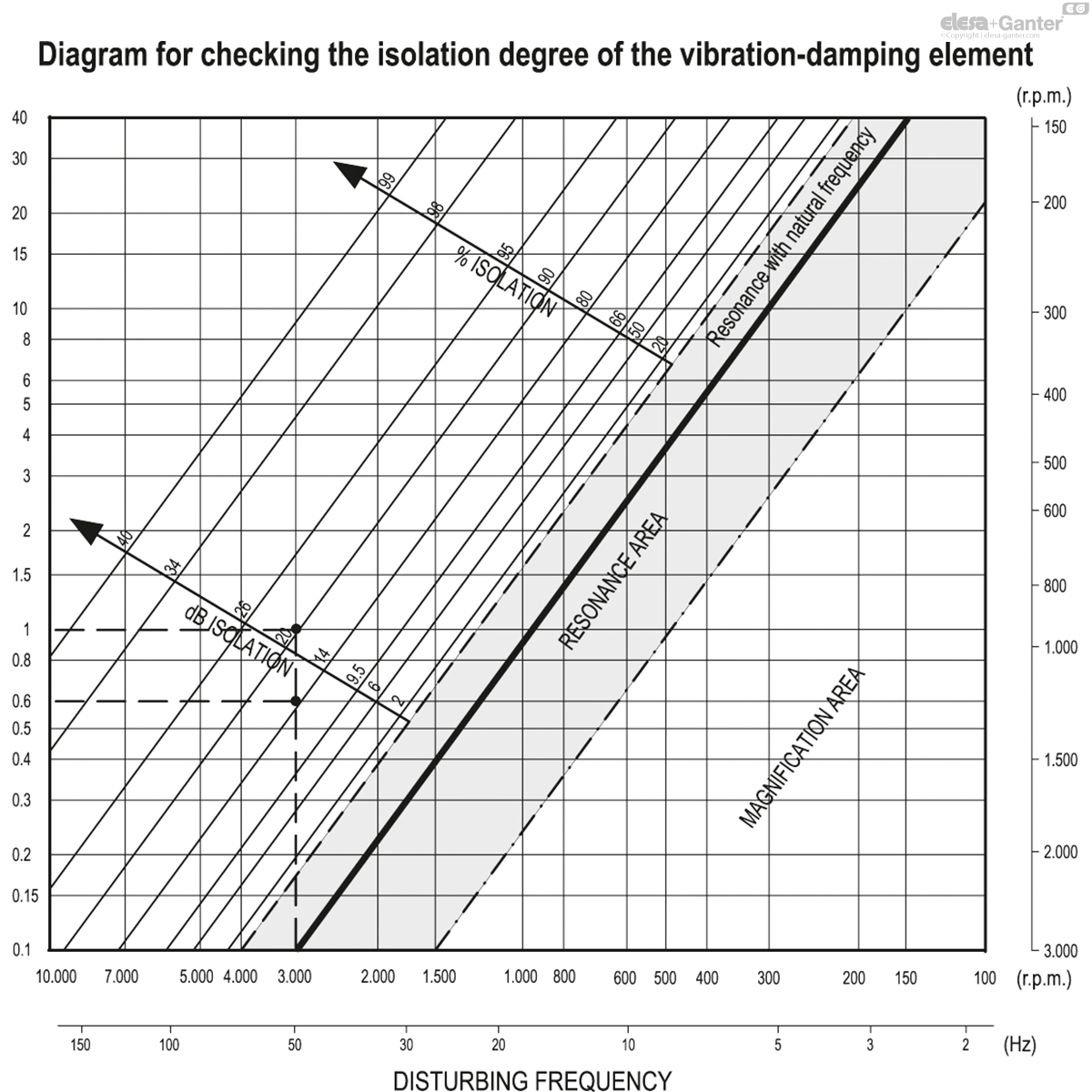

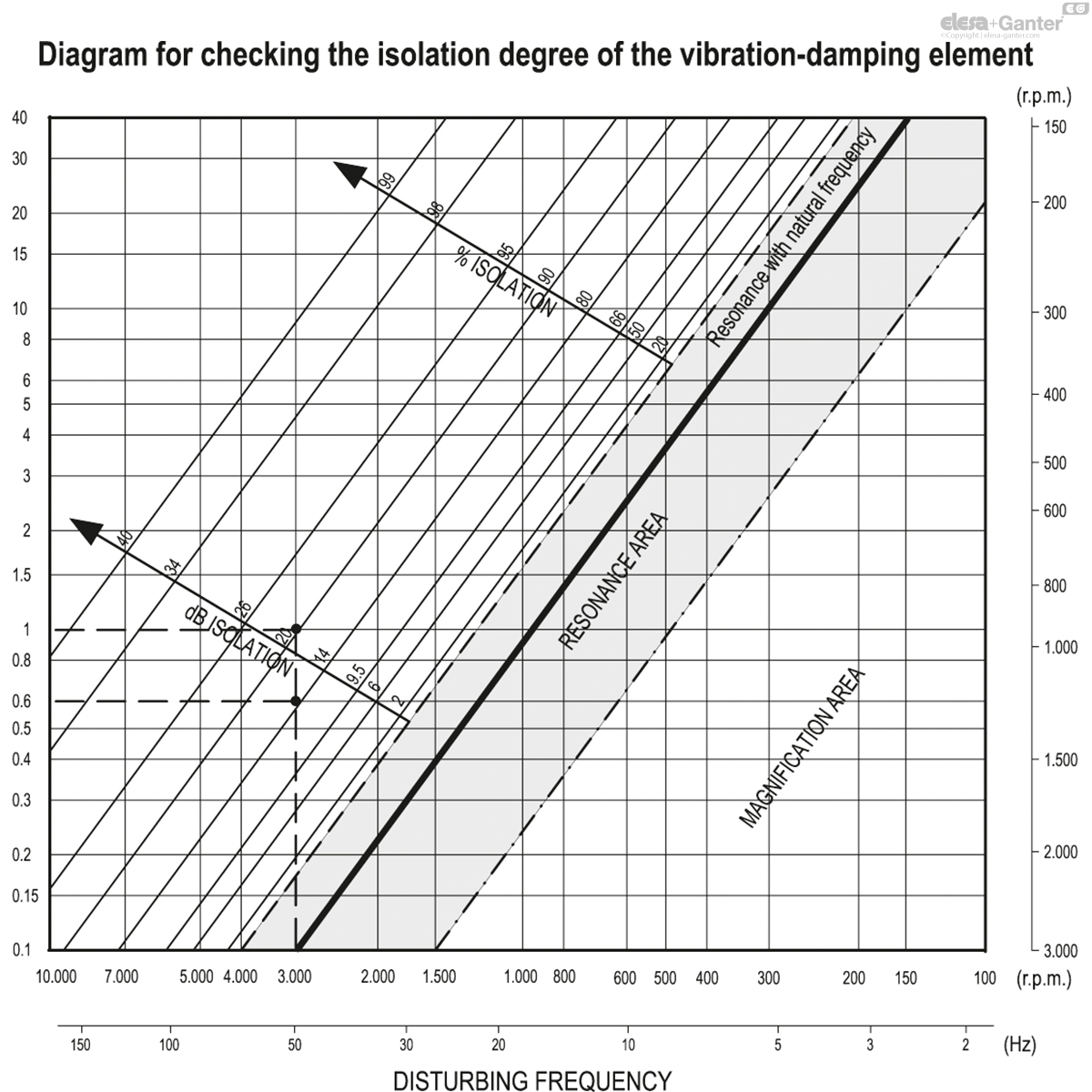

- with reference to the diagram for checking the isolation degree, intersect the disturbing frequency value with the isolation degree required (each isolation degree corresponds to a line in the diagram) and define the deflection [in mm];

- divide the load applied onto the vibration-damping element by the deflection value to obtain the required rigidity of the vibration-damping element;

- compare the rigidity obtained with the rigidity shown in the table and choose the vibration-damping element which presents the nearest value (lower) to the calculated one.

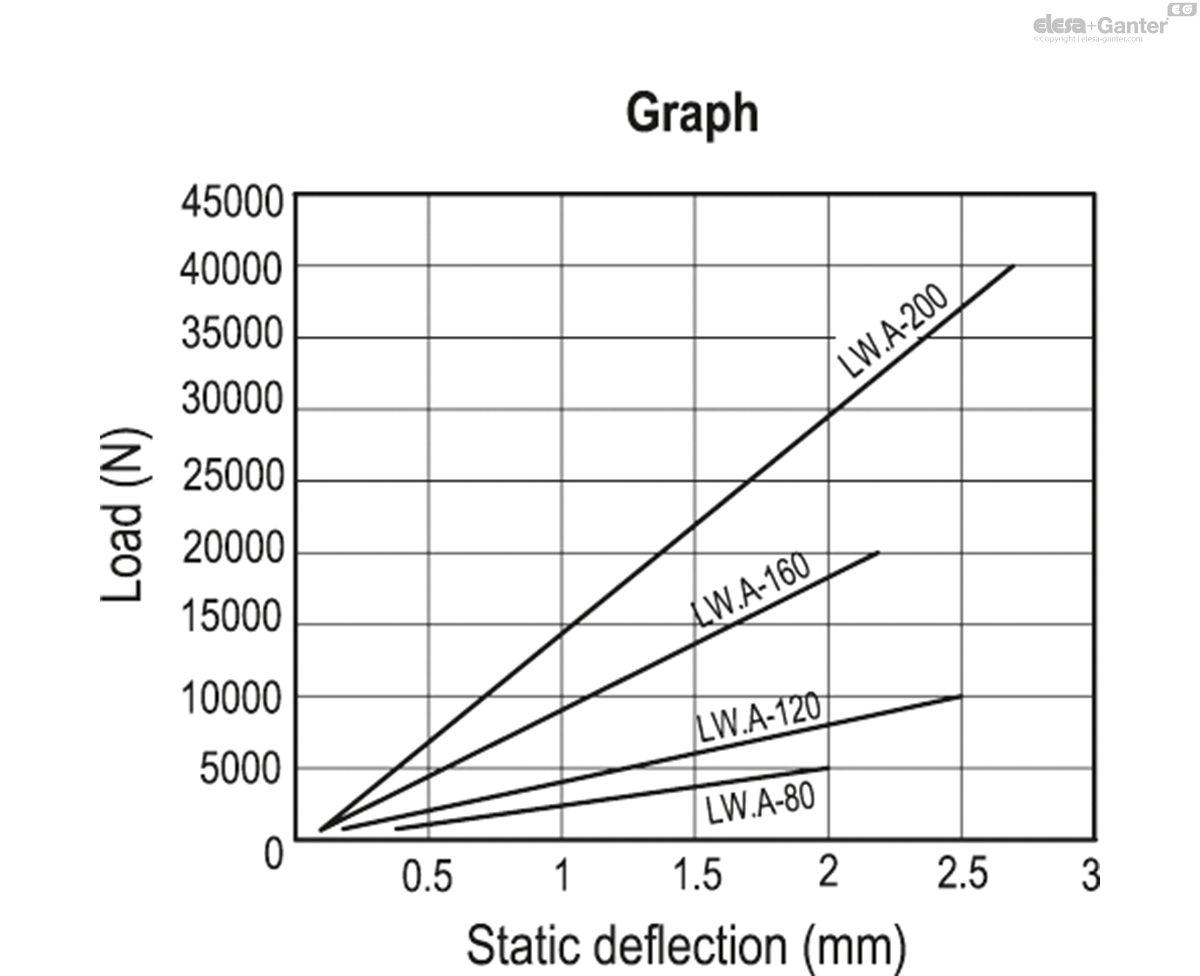

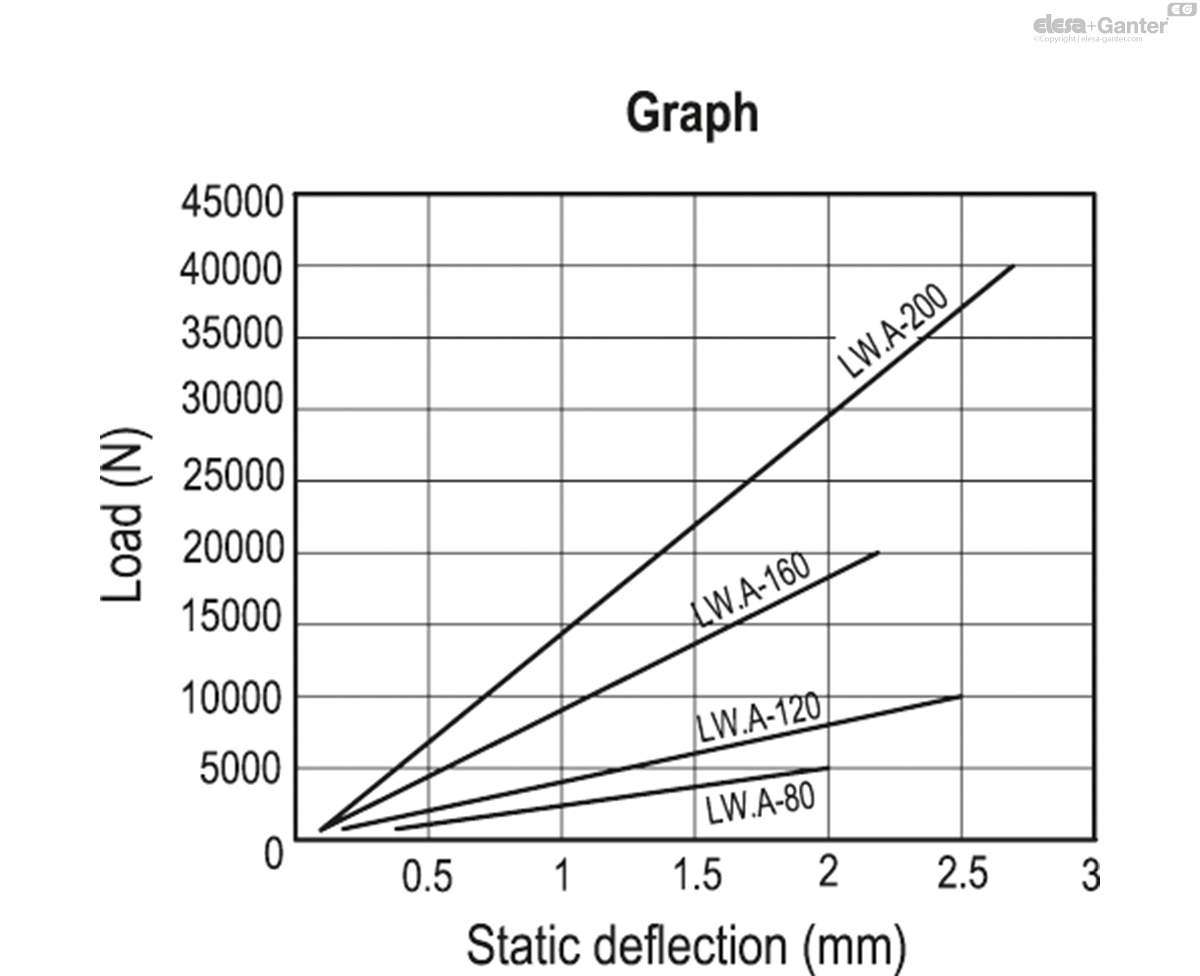

- the deflection of the vibration-damping element chosen can be obtained in the graph on the basis of the load;

- intersect the disturbing frequency value with the vibration-damping element deflection value in the diagram to obtain the isolation degree offered by the vibration-damping element chosen;

- compare the obtained value with the isolation degree required.

- Conditions of use: disturbing frequency = 50 Hz (3,000 r.p.m.); load applied to every levelling element = 4,000 N; a 80% isolation degree is required;

- diagram shows that with a 50 Hz disturbing frequency and an isolation degree of 80%, the deflection obtained is 0.6 mm;

- divide the load applied by the deflection obtained to define the rigidity required, which is 4,000/0.6= 6,666 N/mm;

- compare the rigidity value obtained (6,666 N/mm) with the values reported in the table. This value is within the rigidity value reported in the table for LW.A-120 (4,000 N/mm) and LW.A-160 (9,000 N/mm). Choose the vibration-damping element with the lower value that is LW.A-120.

- graph shows that LW.A-120 (4,000 N/mm) deflection is 1mm.

- by intersecting the deflection value with the disturbing frequency of 50 Hz in the diagram, the isolation degree obtained is 90%.

This value is even greater than the required one; your choice has proved to be correct.

Assembly instructions

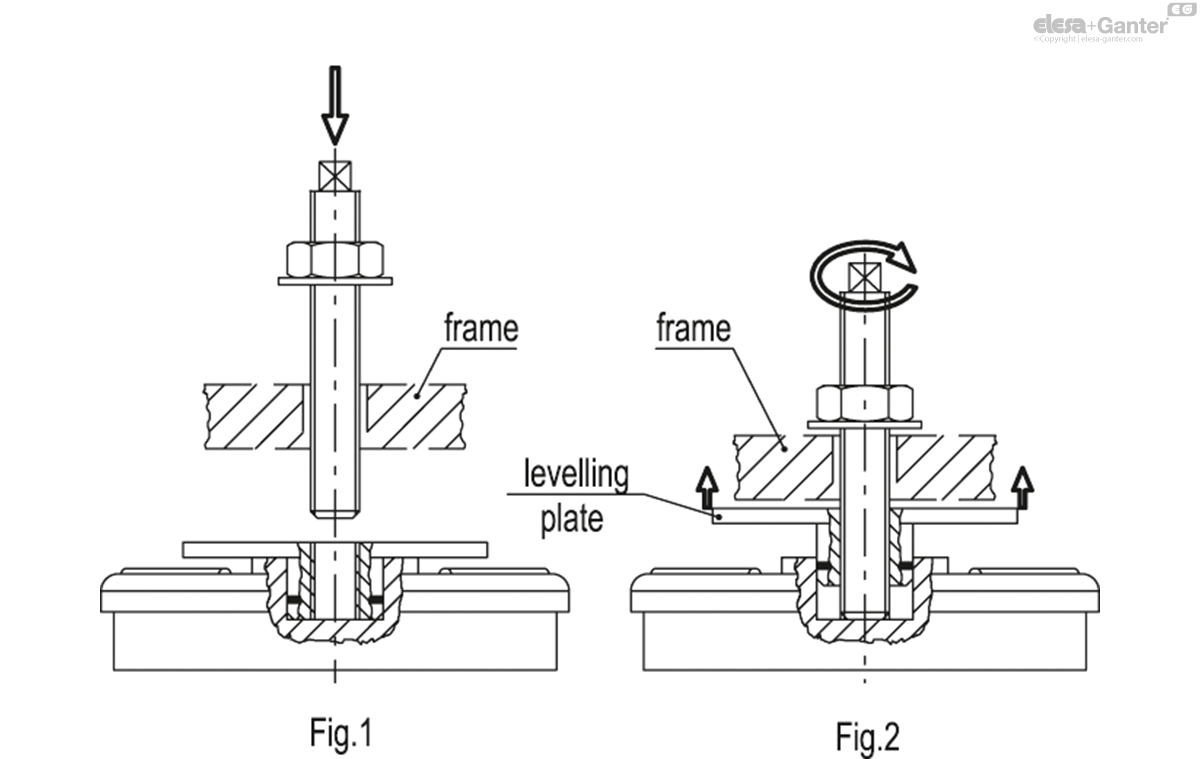

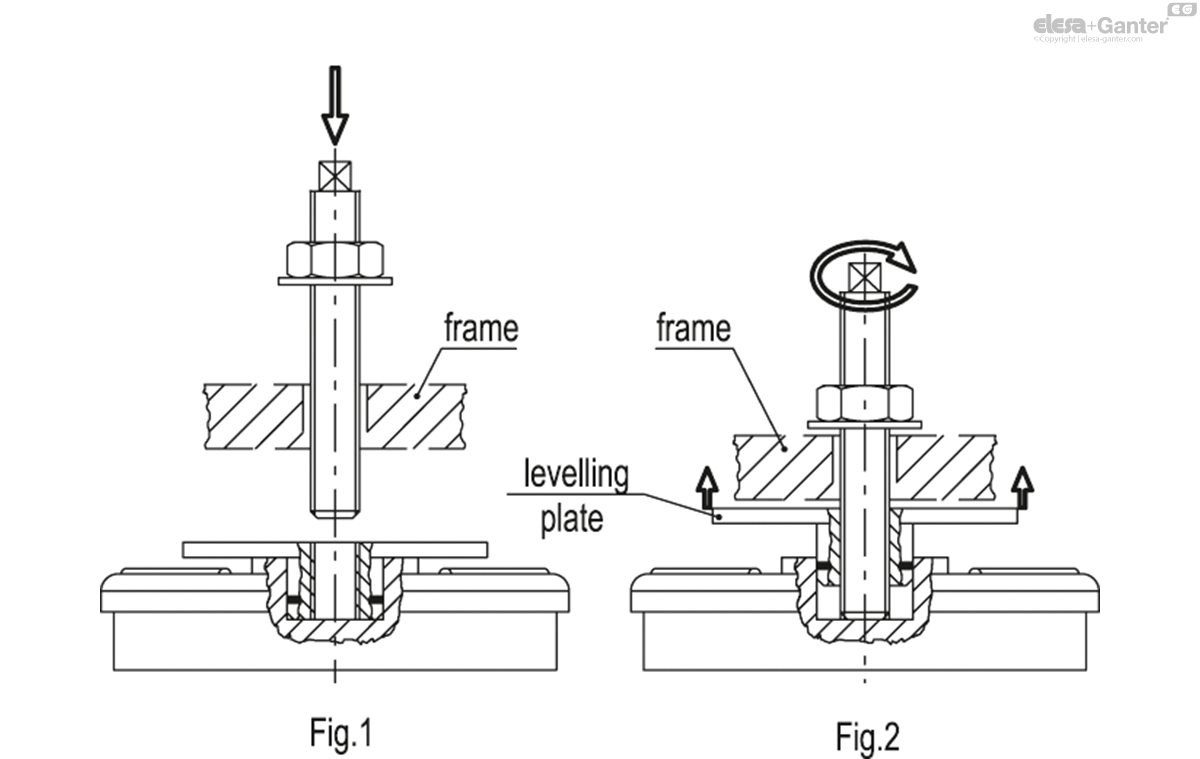

- Put the base of the vibration-damping element under the machine and insert the stem through the hole (not threaded) in the frame of the machine (fig.1)

- Turn the square end of the stem to take the levelling plate in contact with the machine thus obtaining the levelling required. Then lock with nut and washer (fig.2)

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.

Related Products