GN 810

Toggle ClampsDescription

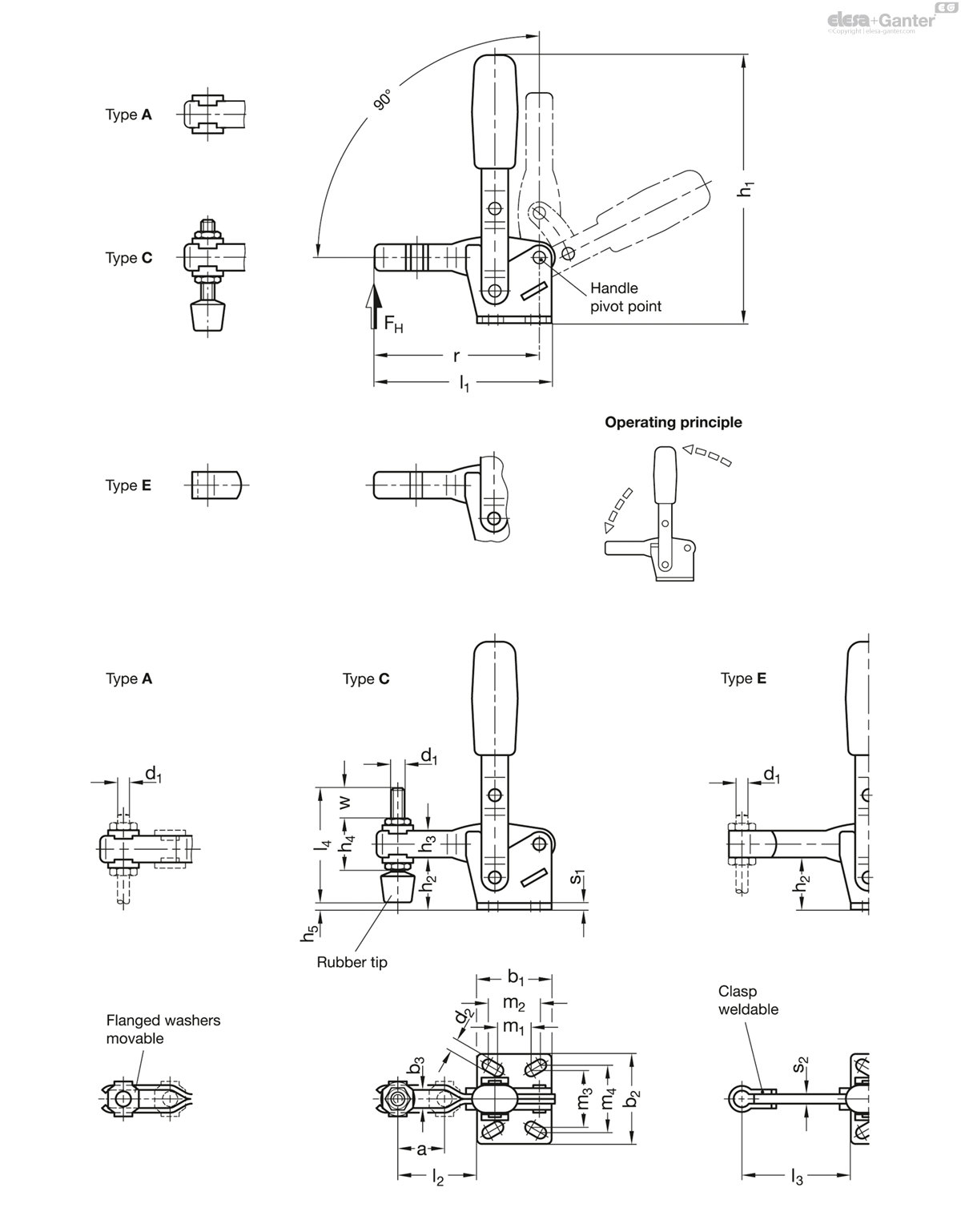

Types

- Type A: U-bar version, with two flanged washers

- Type C: U-bar version, with two flanged washers and GN 708.1 spindle assembly

- Type E: Solid bar version, with clasp

Version in Steel

- Case-hardened Steel C10, zinc plated, blue passivated

- Bearing pins tempered

- Bearing rivets (for size 230 and up), case-hardened

All moving parts

lubricated with special grease

Hand grip

High quality, oil resistant red plastic

Spindle assembly GN 708.1, Type A

- Steel, zinc plated

- Rubber tip 85 Shore A

Version in Stainless Steel NI

Stainless Steel AISI 304

All moving parts

lubricated with special grease

Hand grip

High quality, oil resistant red plastic

Spindle assembly GN 708.1, Type A

- Stainless Steel AISI 304

- Rubber tip 85 Shore A

GN 810 vertical acting toggle clamps work according to the toggle principle: lever and clamping bar move in the same direction. In the clamped position the operating lever is in its vertical position.

Vertical acting toggle clamps in the U-bar version with two flanged washers (Type A) can accommodate an application specific clamping screw. A spindle assembly with neoprene rubber tip is also included for Type C.

Type E version can either be utilized by welding the clasp which can then accommodate an application specific hold-down fastener component, or by utilizing the bar in conjunction with GN 809 clamp mounts to hold the work piece in place.

- General information for toggle clamps

- Spindle assemblies

- GN 801 clamp mounts for toggle clamps (for Type A)

- GN 809 clamp mounts for toggle clamps (for Type E)

GN 810-NI

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.