GN 418.2

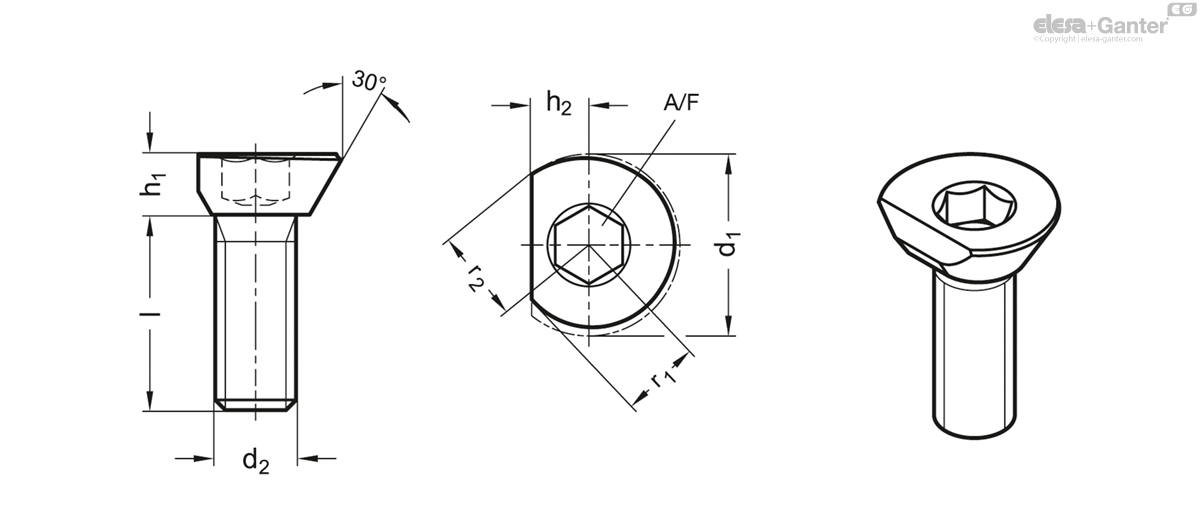

Cam point screwsDescription

Type

Type R: Clamping by clockwise rotation

(d2 = right-hand thread)

Steel

- case hardened HRC 56 ±1

- Tensile strength class 8.8

- zinc plated, blue passivated

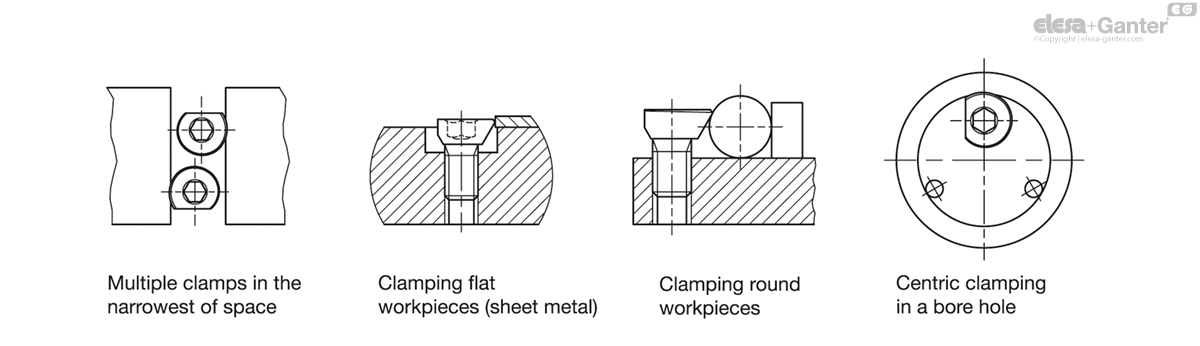

Cam point screws GN 418.2 are sturdy and compact elements, requiring a minimum of installation space and offering ultimate convenience and ease in handling.

The clamping forces F given in the table refer to the maximum permitted tightening torque and the specified screw-in depth t.

- Strength values of screws

Function

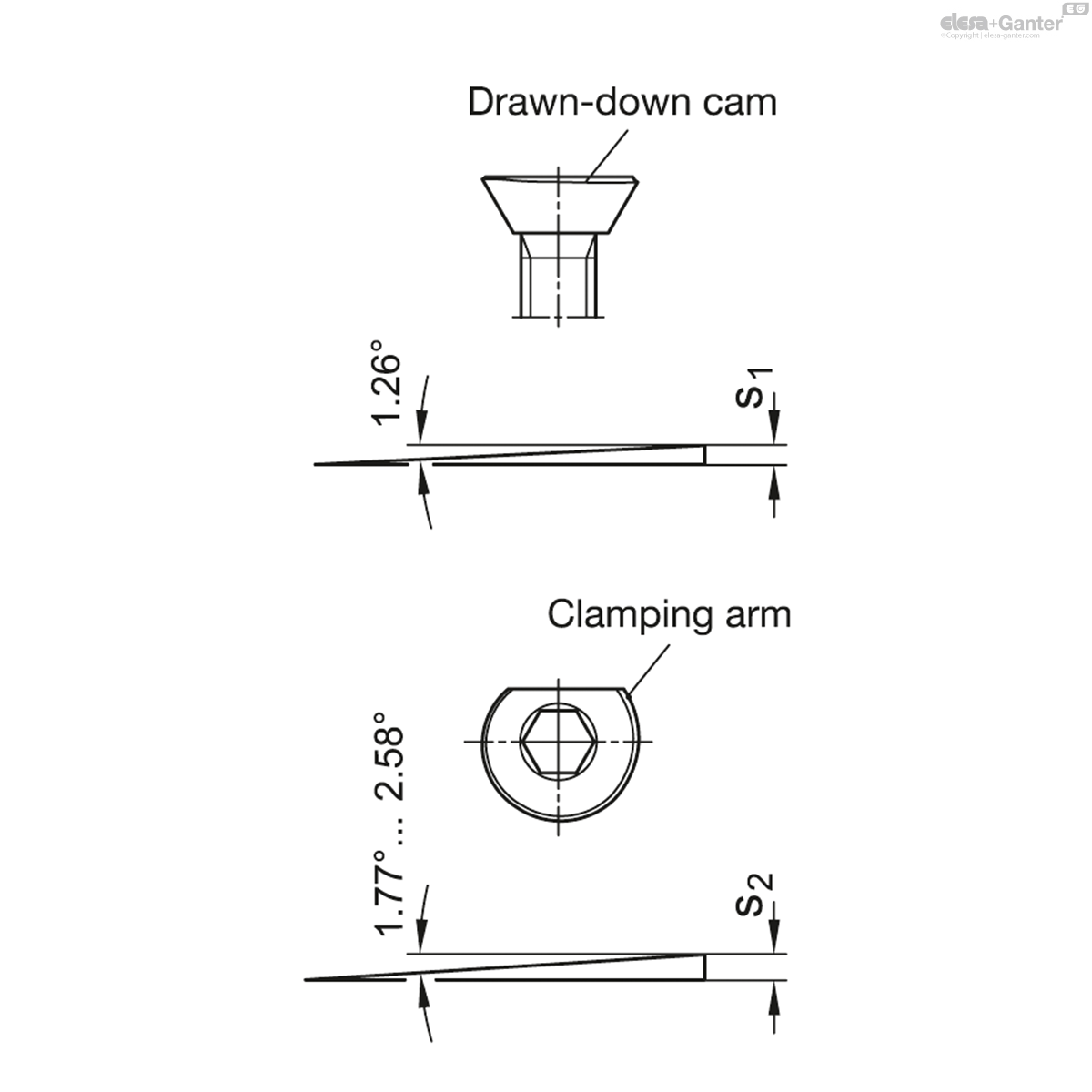

The head of the cam point screw has two cams: a radial clamping cam (with additional 30° taper) and an axial draw-down cam. The cam ensures that the clamping force is the same in any angular position. The cam is also self-locking.

Force components act on the clamping point which generate a draw-down effect and which, in addition to the friction, cause the workpiece to be pressed against a fixed stop. An additional draw-down effect is created by the thread and the 30° taper.

To ensure safe and secure clamping in every application, a right-hand version (with right-hand thread) and a left-hand version (with left-hand thread) is available.

Assembly instructions

- Position the thread bore(s) as specified

- Screw the cam point screw in to the desired height and place it with its flat side facing the workpiece (note the minimum screw-in depth t)

- For clamping effect above the head taper, the minimum clamping height should be h2

- A turn of approx. 135° is required for clamping

GN 418.2

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.