GN 210

Gear Levers

Description

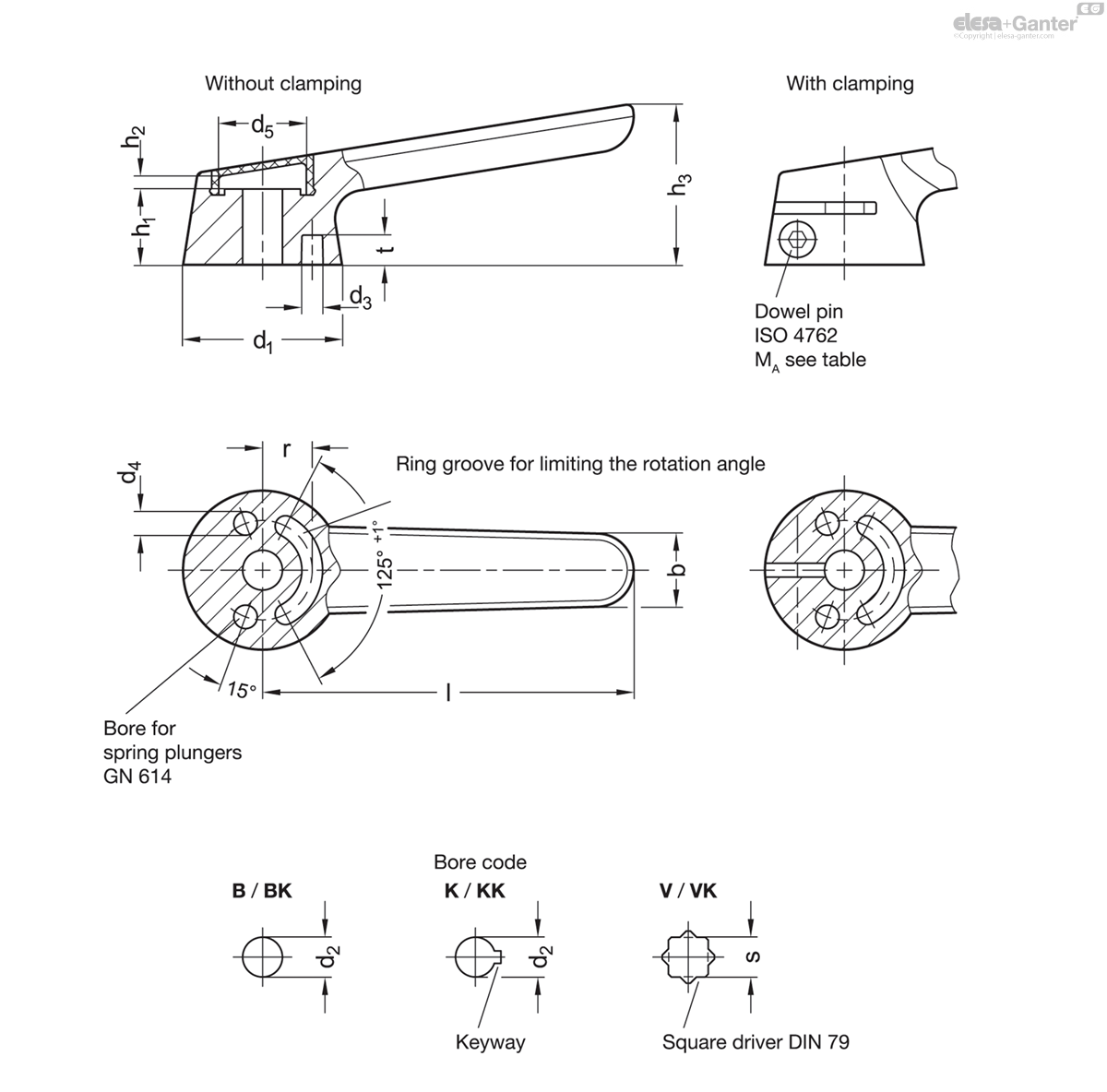

Bore code

- Version B: Without keyway, without clamping

- Version BK: Without keyway, with clamping

- Version K: With keyway, without clamping

- Version KK: With keyway, with clamping

- Version V: With double square, without clamping

- Version VK: With double square, with clamping

Coding (cap)

- Coding N: Plain

Handle

Zinc die casting ZD

- Powder coated

- Silver, RAL 9006, textured finish SR

- Black, RAL 9005, textured finish SW

- Keyway DIN 6885-1

- P9 for type K

- JS9 for type KK

Cap

Plastic, polyamide (PA)

- Removable

- Gray for SR

- Black for SW

Socket cap screw ISO 4762

for bore code BK / KK / VK

Stainless steel

Gear levers GN 210 are used to drive shafts, such as for switching gears and engaging clutches or operating valves and latches.

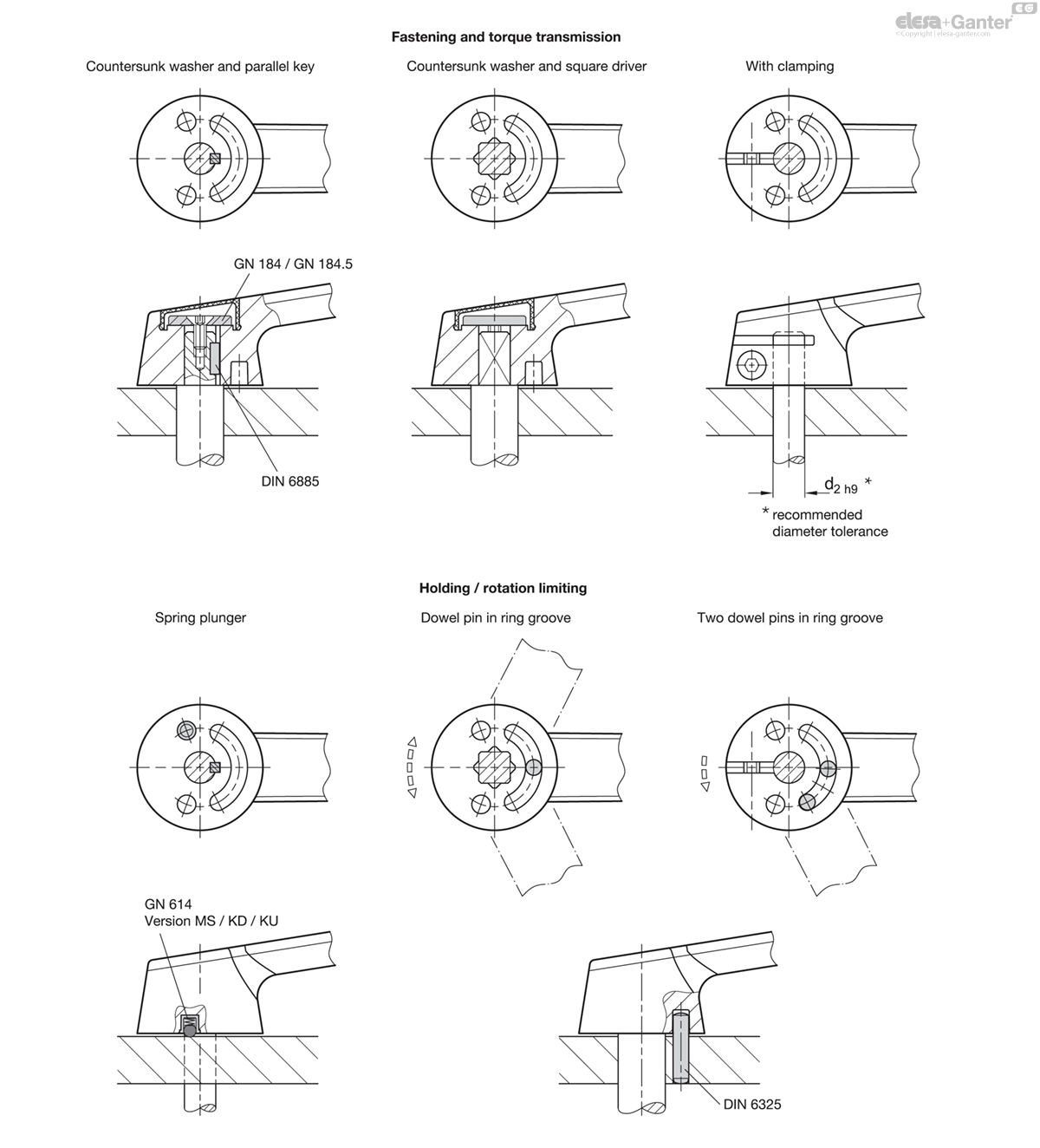

The torque is transmitted through a positive connection either via a parallel key or a square drive. This ensures a defined angular position between the shaft and the handle. The angular position can be freely definedusing gear levers with smooth bore.

Gear levers with parallel key or square drive can be secured axially with a countersunk washer. The versions with clamping transmit torques and forces with zero backlash via frictional locking and secure the hub axially. They are easy to install and allow for subsequent adjustment.

The rotational angle of the gear levers can be held with spring plungers or limited with dowel pins. An application-specific rotational angle can be defined by using two dowel pins.

- DIN 6885 Parallel Keys

- GN 184 Countersunk Washers

- GN 184.5 Countersunk Washers

- GN 614 Spring Plungers

- Keyways DIN 6885-1

- Squares DIN 79

- ISO-Fundamental Tolerances

- Plastic Characteristics

GN 210-KK

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.