GN 115.7

Latches with Cabinet U-Handle

Description

Types

- Type DK: With triangular spindle

- Type VK7: With square spindle

- Type VK8: With square spindle

- Type SCH: With slot

- Type VDE: With double bit

Cabinet U-handle

Zinc die casting

Powder coated

- Black, RAL 9005, textured finish SW

- Silver, RAL 9006, textured finish SR

Other parts

Steel

Zinc plated, blue passivated

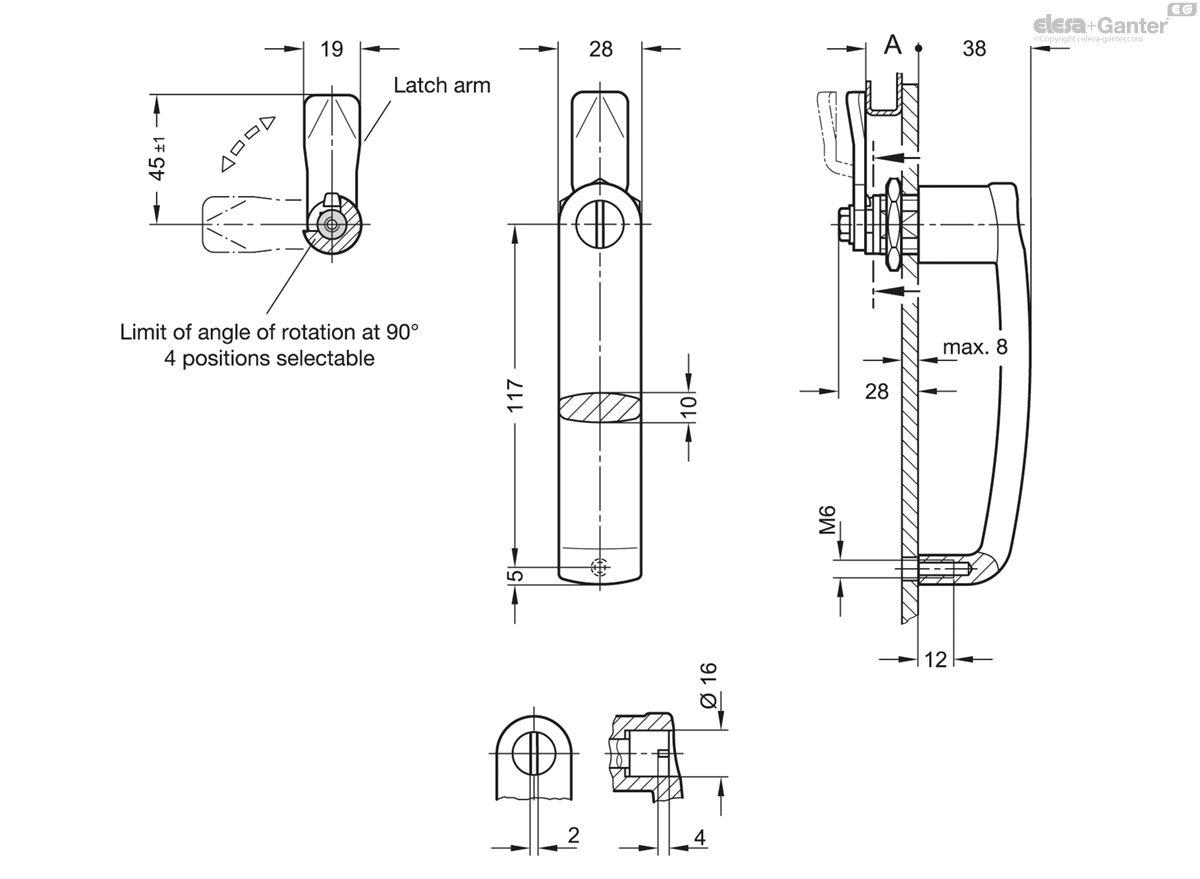

Latches with cabinet U-handle GN 115.7 are used when the application requires both a locking mechanism and a handle. They lock by a turning operation limited to 90° which moves the latch arm in the locked position behind the door frame. The bevels of the latch arm ease the closing of the door.

Latch arms are available with different bend angles to cover a latch arm distance A from 4 to 50 mm. The latches with cabinet U-handle GN 115.7 are supplied with loosely enclosed latch arm.

The cabinet U-handle with integrated latch arm is an attractively designed and cost-effective solution.

- GN 119.2Socket Keys

- GN 120.2Protective Guide Plates

- GN 120.3Internal Cabinet Handles

- List of latch types

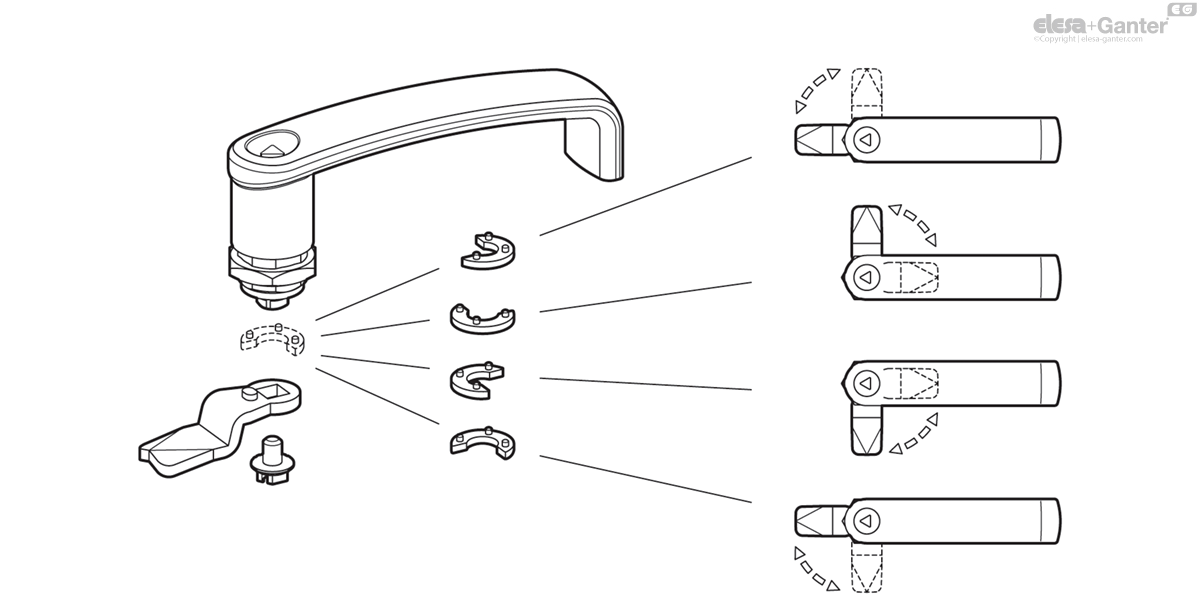

Depending on the installation situation, the 90° turning range of the latch arm can be defined by means of a plug-type element, which can be mounted in 4 different positions.

This allows the latch with U-handle to be used in any attachment position and regardless of the turning and locking direction or of the narrow side of the door. Subsequent repositioning of the 90° rotary range is possible, if necessary.

The possible plugging options and the resulting 90° rotary ranges are shown in the outline drawing.

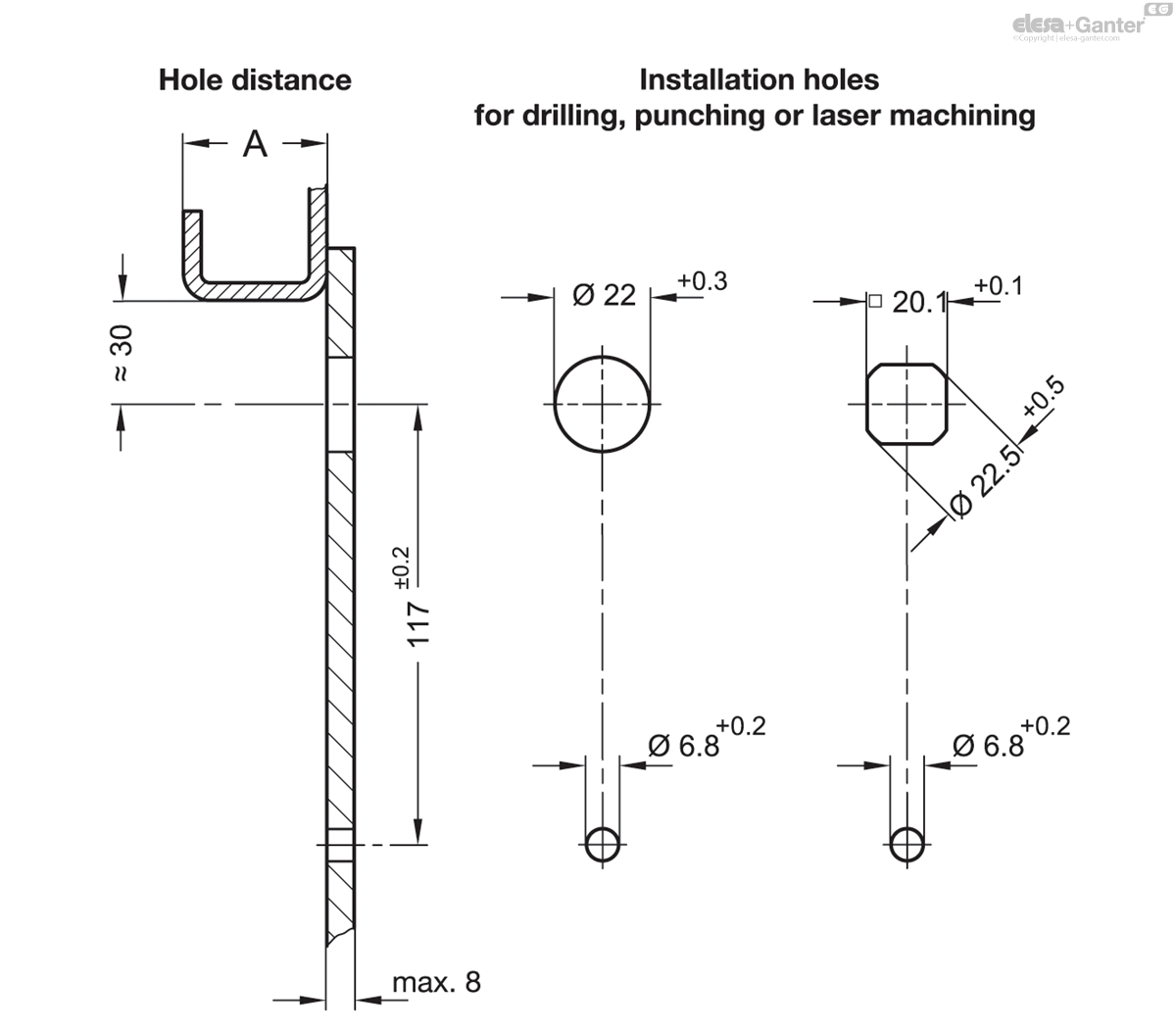

For installation, the door, cover or hatch is fitted with two holes according to one of the two outline drawings.

If preassembled (cabinet U-handle including latch arm), the latch can be inserted through the hole from the front. The mounting nut can then be pushed over the latch from the back and bolted in place. The second end of the cabinet U-handle is secured with an M6 mounting screw (not included). Finally, both elements are tightened.

The required installation holes in the door leaf, is usually generated by punching or laser machining in series production.

GN 115.7-SCH

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.