FHT

TubesDescription

Material

Acetal-based technopolymer (POM), blue.

Standard executions

- FHT: modular tubes, pre-assembled in segments.

- FHT-C: modular tubes, pre-assembled and wound along a reel.

Features

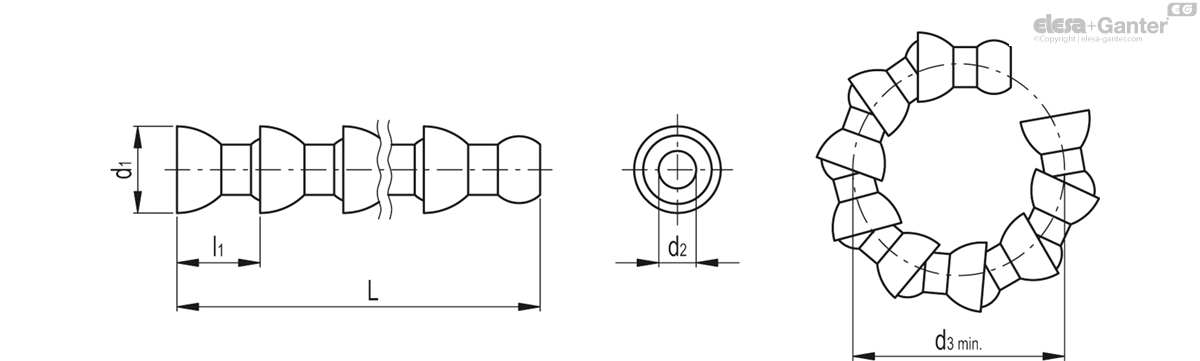

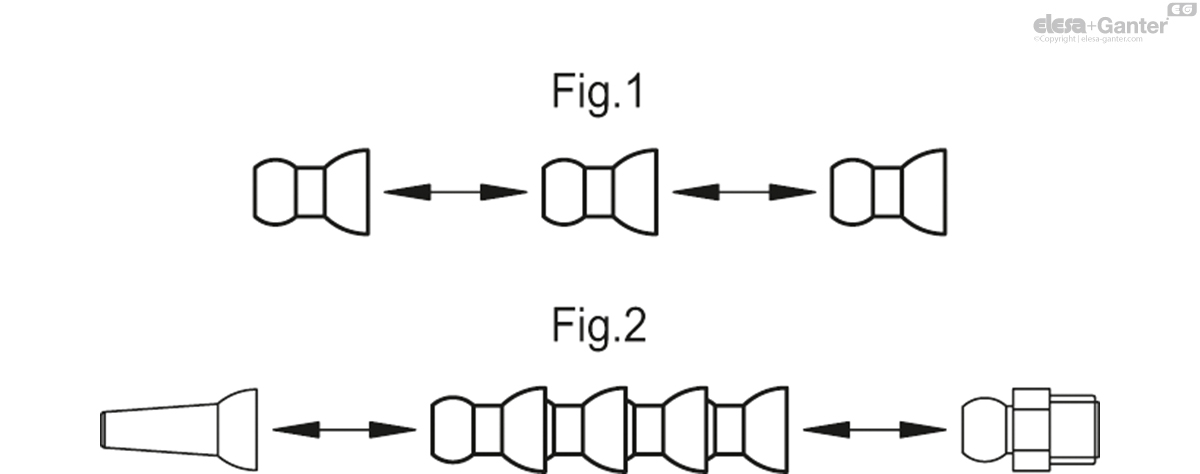

The modular structure, formed by means of the snap mounting of the individual segments (Fig.1), allows the lubricating jet to be channelled in the desired direction.

The length of the tube can be adapted to the specific application by adding or removing the appropriate number of segments via the snap fitting.

To form a complete coolant hoses, coupling with a nozzle FHN, and a fitting is required FHJ (Fig.2).

Assembled without using seals, the system should therefore not be considered watertight.

Max input pressure: 4 bar (FHT.1/4), 2 bar (FHT.1/2).

Chemical compatibility

Material resistant to detergents, lubricants and oils, avoid contact with strong acids and bases.

To use fluids other than those listed, contact Elesa’s technical department.

In any case we suggest to verify the suitability of the product under the actual working conditions.

Special execution on request

Tubes made from raw materials suitable for contact with food (FDA CFR.21 and EU 10/2011).

Accessories on request

Pliers to assemble the components.

FHT-C

| L | d1 | d2 | d3 min. | l1 | For modular system | Number of segments | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Code | Description | Actions | ||||||||

| 471202 | FHT.1/4-C-7500 | 7500 | 16 | 7 | 48.5 | 15.1 | 1/4 | 495 | 1200 |

|

| 471207 | FHT.1/2-C-7500 | 7500 | 26 | 12 | 59 | 19.5 | 1/2 | 384 | 2000 |

|

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.