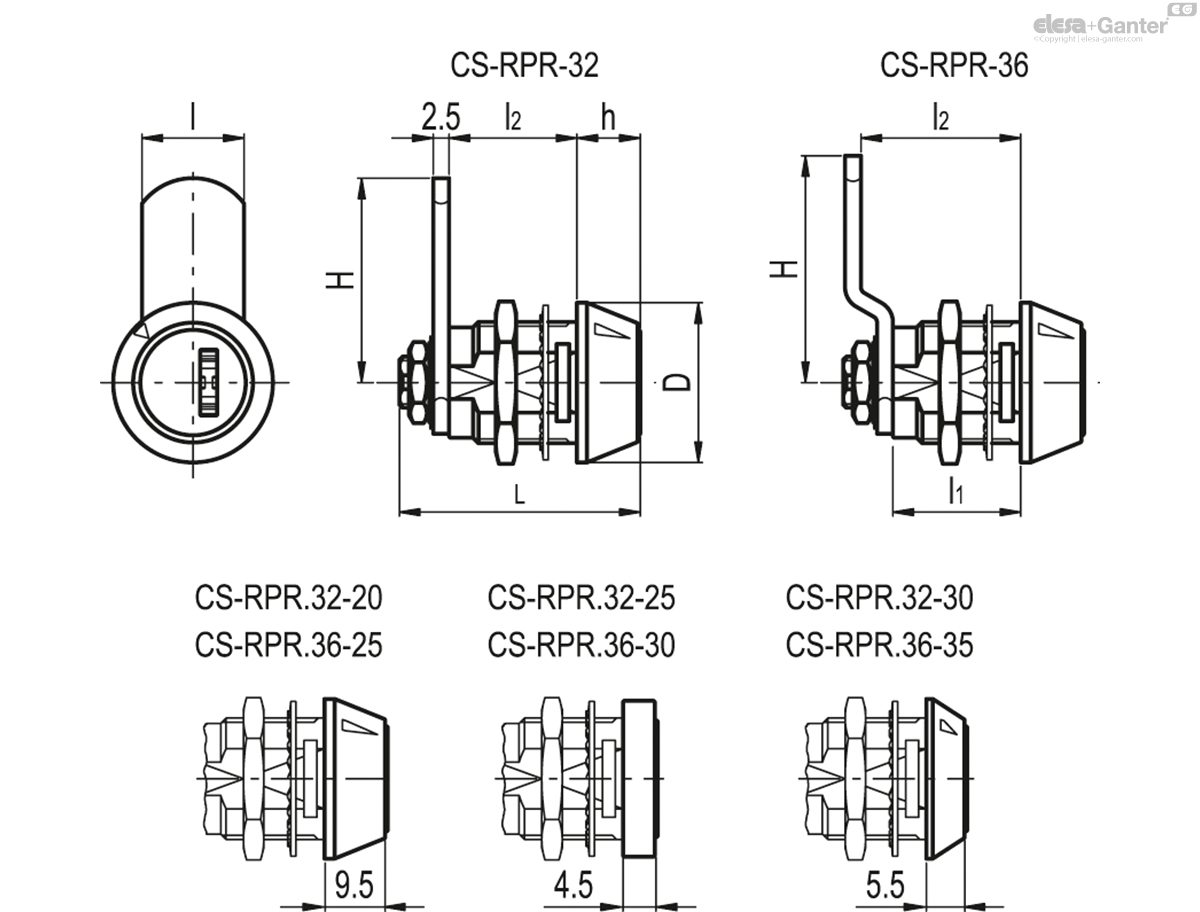

CS-RPR.

Lever latchesDescription

Lock

With opposing blades and double profile key with internal track, (to be ordered separately, see below keys kit). 9.791 different lock combinations.

Stator and rotor

Chrome-plated zinc alloy with drill-proof hardened steel plate and stainless steel front plate.

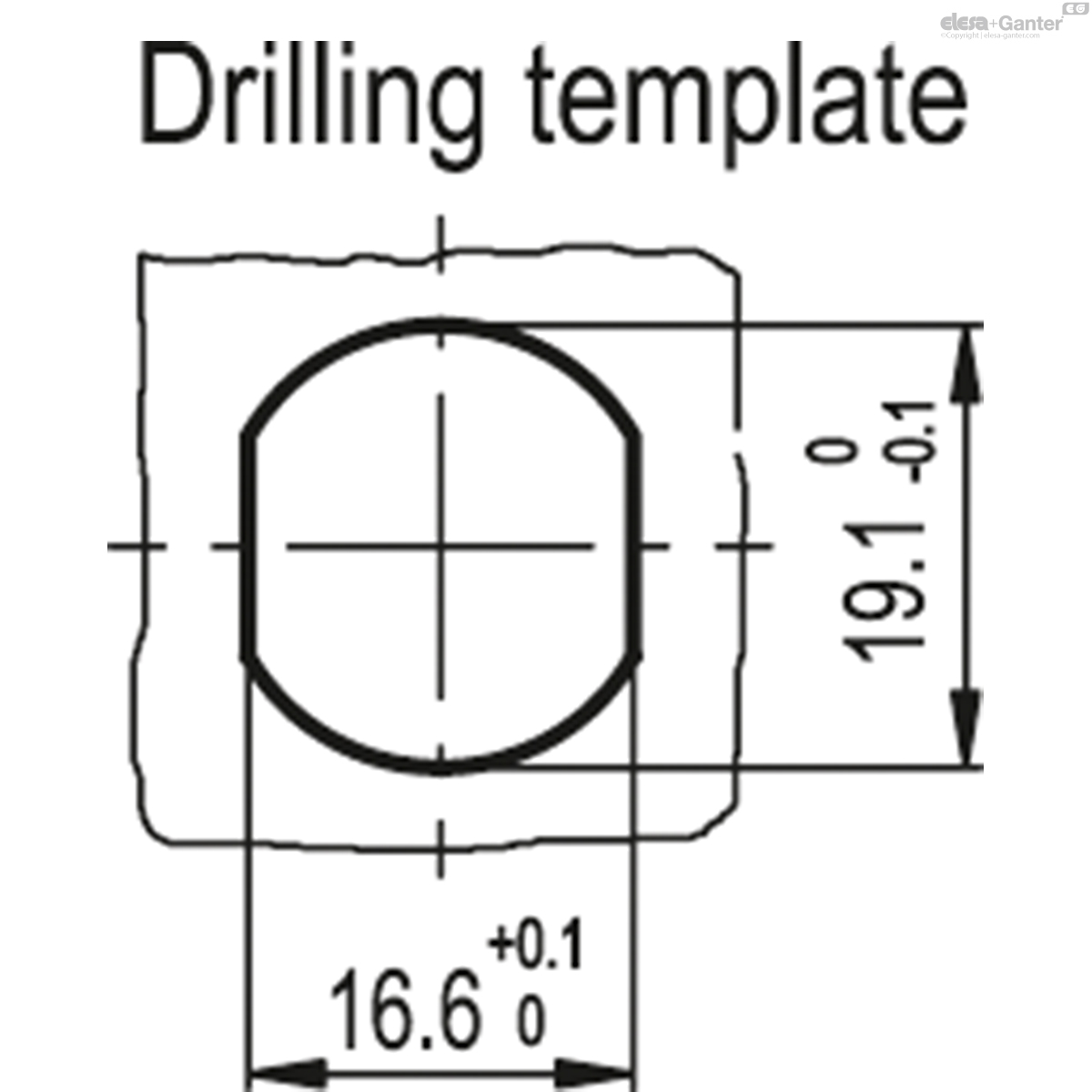

Nut

Brass M19x1

Toothed washers

For zinc-plated steel stator, for steel screw.

Closing lever

Zinc-plated steel, thickness 2.5 mm.

Nut

Brass.

Screw

Zinc-plated steel (only for executions CS-RPR.32-30 and CS-RPR.36-35).

Rotation

180°, with key removable in two positions.

Keys kit

The KCR keys kit (to be ordered separately) consists of a brass programming key and some nickel silver keys for normal use.

- KCR-05: 1 programming key and 5 keys for normal use.

- KCR-10: 1 programming key and 10 keys for normal use.

- KCR-01: 25 keys for normal use.

Special executions and accessories

- Closing levers in other dimensions.

- Other keys kits with different programming.

Features and applications

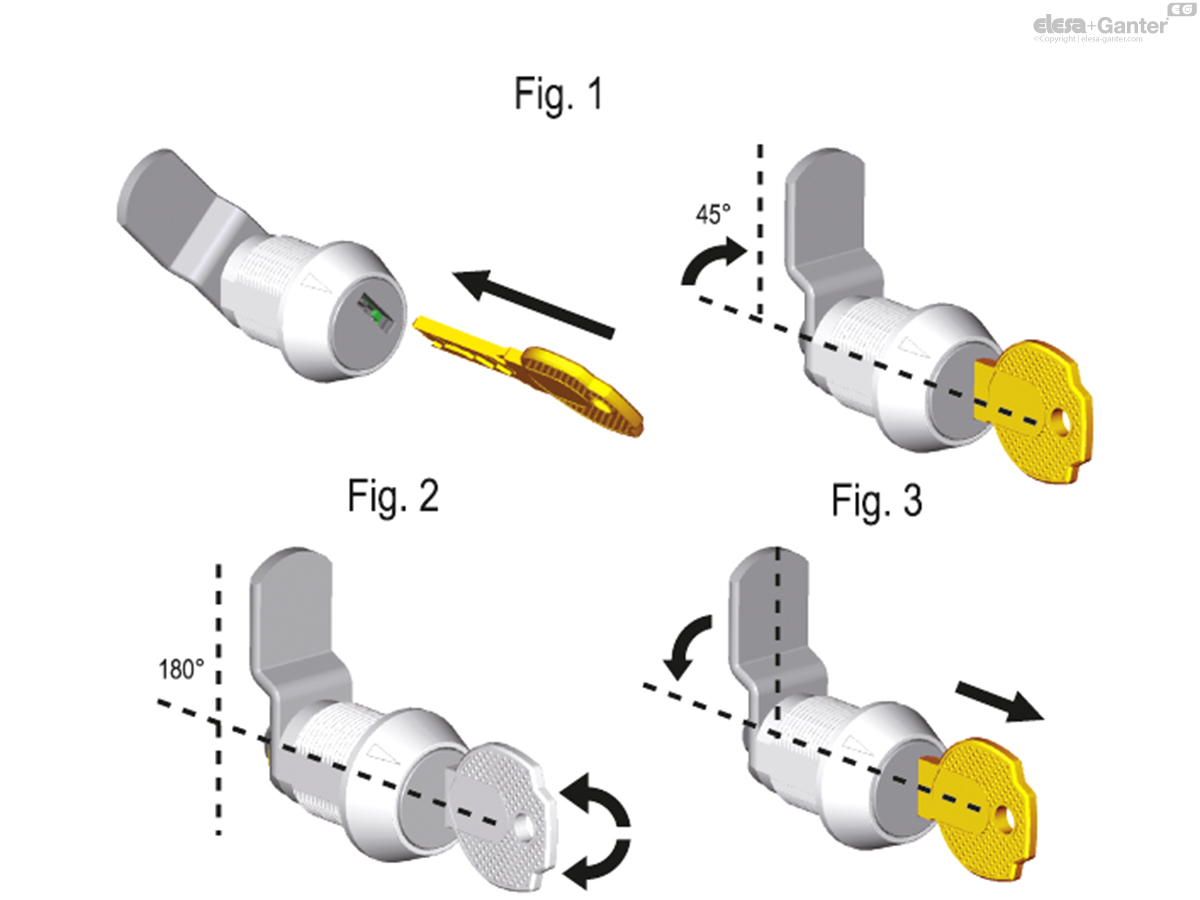

The CS-RPR are supplied non-programmed with the rotor positioned in line with the index marked on the stator front surface.

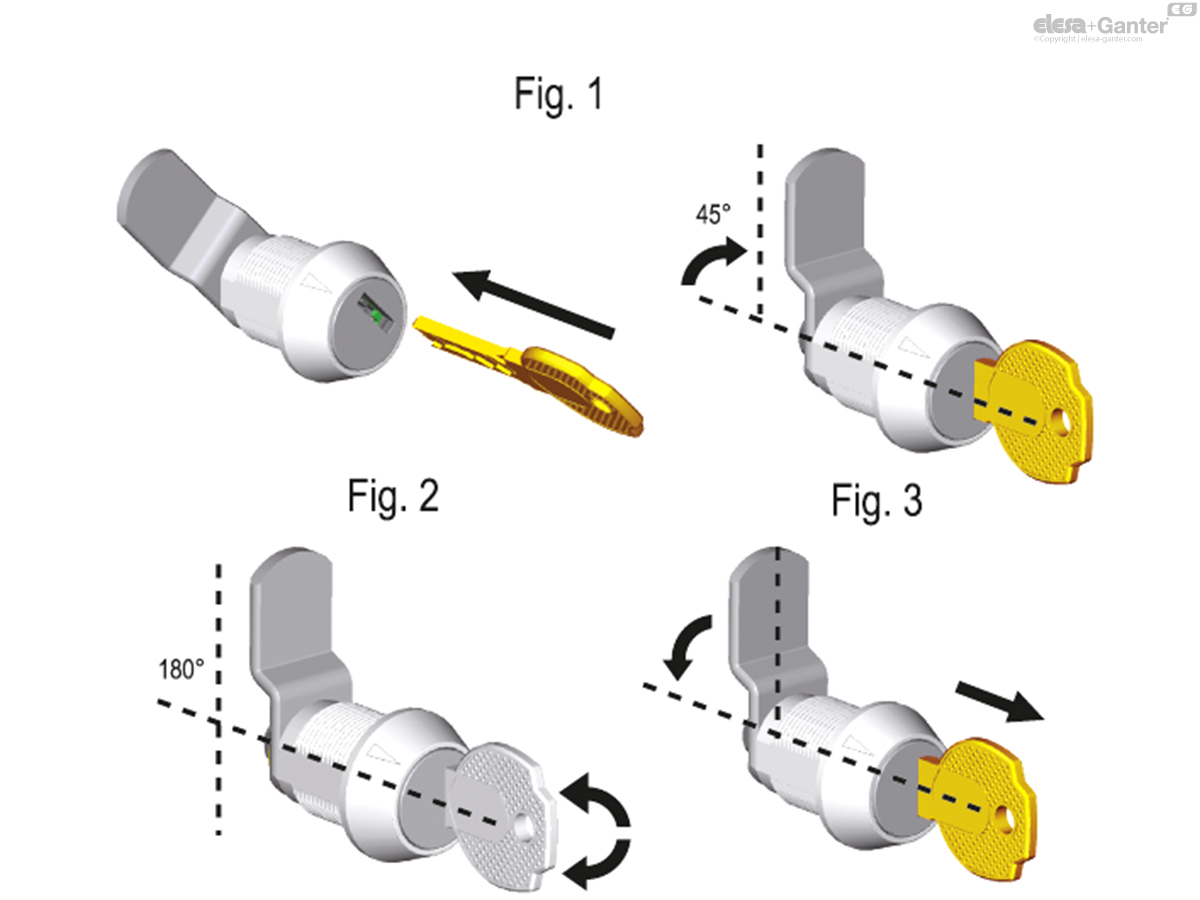

- First programming: insert the programming brass key and turn the lock clockwise by 45° (Fig.1). The lock is now programmed. Insert the normal use key in nickel silver to lock or unlock the latch (Fig.2).

- Reprogramming of the lock: insert the brass programming key used at first and turn the lock anticlockwise by 45° until the rotor is in the neutral position (Fig.3). Remove the key, insert now a new programming key (new kit) and turn it clockwise by 45° (Fig.1).

Now the lock has been reprogrammed with a new combination and the nickel silver normal use keys, included in the kit of the new programming key, must be used to lock or unlock the latch (Fig.2).

Enquiry Now

To allow us to respond to your enquiry promptly, please provide all required information.